With over three decades of experience in India’s automobile, tractors and construction equipment sectors, Sandeep Singh understands more than most the ups and downs the market is prone to experience. When he joined Tata Hitachi Construction Machinery Co Ltd in August 2015, the industry was only just starting to emerge from one of its low phases, yet there was more than a glimmer of hope for the Managing Director to hold on to as he started out in his new role.

“A new government had just taken over and we knew that, with it, there would be a greater emphasis on infrastructure,” he explains to The CEO Magazine from the company’s corporate headquarters in Bangalore. “We also knew that this would bring more opportunities in the market and that the industry would start to grow again.”

The question for Sandeep, however, was whether Tata Hitachi – a 60–40 joint venture between Japan’s Hitachi Construction Machinery Co Ltd and Tata Motors Ltd – was well placed to capitalise on this growth potential.

“The company has history and legacy, and we have always enjoyed a good reputation in the market, but we did have a higher cost of production,” he explains. “We also had some issues with regard to product quality and customer satisfaction.” And he wasn’t the only one facing a deflated market.

“When the industry goes down consistently for four or five years, no-one is making any money; neither the organisation, nor the dealers, nor the vendors,” he explains. “It was quite a challenge to motivate people to improve the quality level and to focus on customer service.”

Align, focus, improve and build are the words Sandeep carefully chooses to describe the approach he took. “My main tasks were to align people, focus on quality and improve our deliverables to our customers,” he explains. He also worked to build trust between the stakeholders, “such as our vendors, who supply us with components to manufacture our equipment, and our dealers, who offer both sales and services to the end customer,” he continues.

“My main tasks were to align people, to focus on quality and to improve on our deliverables to our customers.”

With his team in consensus, he also set three guiding principles for the business to operate by. The first was ‘Right Machine at the Right Time’, a response to the inconsistent forecasting and production delays that had been plaguing the company.

“We absolutely needed to improve on the forecasting from our sales and marketing team,” he reflects. Clear processes and systems were also required to transfer that information to the manufacturing units, who could then pass it on to its network of vendors.

Here comes the sun

It is predicted that, by 2025, India will join China and the US as the world’s largest three power-consuming nations. As the government attempts to address the country’s growing appetite for power, and a supply that is renowned for being inconsistent, it has set certain renewable energy targets: 175 gigawatts by 2022 was set in 2015. In July this year, this was increased to 500GW by 2030.

As part of this initiative, Tata Hitachi announced in March 2019 that its plant in Kharagpur had installed a series of solar panels onsite. The company estimates that this move will generate about 7,000 megawatt hours annually, or 60% of the plant’s power consumption.

“This is expected to bring a CO2 reduction of 3,500 tons per year, with annual power costs falling by INR14.7 million (US$206,000),” it said in a statement to the press.

Kharagpur is the second of Tata Hitachi’s plants to harness solar power. In Dharwad, the equivalent of approximately 75% of its annual power consumption today (or 7,500MWh) comes from renewable sources.

“We have a very large vendor base both in India and abroad, so it’s a three- to four-month cycle. We must be able to plan in advance with them. So that was one area where improvement was imperative,” Sandeep explains, adding that he’s happy with the “very good” results achieved so far.

The second principle was ‘Fix it Right First Time’. “If we have any problems in manufacturing and production, we need to fix them immediately,” he explains. The same approach needed to extend beyond the assembly line into the marketplace as well. “When we go out in the market, if a customer is having any issues with the product, we need to fix the problem immediately in the first attempt, to his satisfaction.

“We’ve really focused on building a very strong level of trust between ourselves and our stakeholders – our vendors and our dealers – to improve the skillset of their people and the systems and processes they work with,” he continues. The results so far are encouraging, although

he acknowledges it is still a work in progress.

‘Quality is not only what we produce, but what we deliver’, was the third, and final, principle established. “Once manufacturing is completed, our products undergo stringent quality checks,” he says. “We are strengthening ourselves to ensure that we give a good-quality experience to our customers by delivering machines on time with proper commissioning and providing operator training,” he says.

After five consecutive years of losses, the company finally posted a net profit in the 2016–17 fiscal year. Beyond the reported figures, Sandeep reflects that the hard work over the past four years has been worth it. “They have been very good for us,” he smiles.

Originally established in 1961 as the construction equipment division of TATA Engineering and Locomotive Company (TELCO) to manufacture rope shovels and cranes, Tata Hitachi is currently the only company in India to build such a diverse range of equipment, including 2–40-ton hydraulic excavators for infrastructure, 45–120-ton excavators for mining and 190–800-ton excavators for heavy-duty mining.

It has three plants: Jamshedpur, Jharkhand, opened in 1961 and is where heavy mining machinery is manufactured; Dharwad, Karnataka, has been operational since 1999, particularly for the manufacture of smaller and mid-sized (under 20 tons) excavators and backhoe loaders; and Kharagpur, West Bengal, which dates from 2009 and is its flagship plant. According to the company, this plant is among the biggest construction machinery manufacturing facilities in South-East Asia.

Here, 20-, 30- and 45-ton excavators and wheel equipment are produced for both the domestic and international markets. From October 2019, the machines manufactured in the Jamshedpur plant will move to Dharwad and Kharagpur: TMX20 to Dharwad and the 65-ton and 120-ton machines to Kharagpur.

Tata Hitachi is a leader in excavators for construction and mining, a segment that comprises 90% of the company’s business. Focused on developing global products to suit Indian working conditions, the organisation’s product line-up includes a wide range of excavators: from 2–800-ton excavators to 35–290-ton rigid dump trucks, wheel loaders and backhoe loaders.

Sandeep says that the company continues to focus on strengthening its position in the excavator segment, in which it currently has a 35% share. Along with bringing new models from Hitachi Construction Machinery into local production, upgrades are also being undertaken to some of its existing range to allow them to become the best in the market. “We’ve listened to our customers and are adding some additional features in terms of improving productivity and efficiency,” he explains.

The dependence on a single segment, however, is also something he views as a risk and improving its market position in other product areas is where Sandeep spots the opportunity for growth in the medium to long term.

“In India, the market for excavators is growing at a faster pace than the market for wheel equipment,” he explains. “Therefore, it is important to maintain a leadership position in excavators and achieve a respectable double-digit market share in the wheeled equipment segment in a span of two to three years,” he continues.

In July 2018, the company unveiled a new backhoe loader – SHINRAI, the Japanese word for trust, reliability and confidence. At its release, Sandeep dedicated the machine to the company’s customer and dealer fraternity. “Built in collaboration with Tata Technologies, this all-new backhoe loader with its new and advanced features stands true to its name – SHINRAI,” he said at the launch event. Initially released in South India, with the remainder of the country following, the company hopes to achieve sales of 2,000–3,000 models in its first two years.

Tata Hitachi’s only wheel loader on the regional market, the TL 340H, has been upgraded after a 2018 redesign. The results, so far, are encouraging and vindicate the investment. “From a very small market share, last year we have seen an improvement. We have started to gain momentum, although it will take us another two to three years to reach a respectable position in the market,” he explains.

His background with some of India’s leading businesses, and the lessons learned in a career that has spanned sales, marketing, customer support and general management positions, has shaped Sandeep’s approach and strategy in his current role in the executive suite at Tata Hitachi. A sales role with Mahindra and Mahindra marked the start of his professional journey. “My first assignment was with the tractor division and my second was with the automotive division,” he recalls.

Covering two stints in Toyota – the first with DCM Toyota, followed by a stint at Toyota Kirloskar Motor, where he was the Deputy Managing Director and Chief Operating Officer – exposed him to many assignments. “I was in sales and marketing, as well as dealer development and general management. Then I was put in charge of finance and HR,” he explains. Still with the automotive manufacturer, he was then made Executive Managing Coordinator at Toyota Motors (Asia–Pacific) headquarters, a role that saw him focus on strategic planning while based in Bangkok, where he was located prior to joining Tata Hitachi.

“Across my career, I’ve had great exposure to different kinds of fields, which really helped me when I came on board here,” he says. And he feels his strengths lie in areas where they are most needed. “We are very strong in manufacturing and quality, but while I had a fairly good idea about the manufacturing system – at Toyota I would visit suppliers quite often and interact with our manufacturing head,” he says.

“So that is where my experience at Toyota Kirloskar Motor or Toyota Motors (Asia–Pacific) helped me: to develop systems, to develop KPIs/KRAs for our team, to align people to the company objectives, to look at their aspirations, to develop very good HR policies and to create a good environment in our plants and in our offices,” he explains.

“I’ve also worked on the standardisation of operations across our three plants, as well as fair and transparent communication with our employees and stakeholders. My background and experience really helped me in developing and adding value to the existing systems at Tata Hitachi.

“An important stakeholder for our business is our workforce. Employee engagement is critical to any organisation; therefore, it is a matter of pride for me when the organisation receives recognition as a Great Place to Work for two consecutive years.”

Mining the future

Globally, over one third of all hydraulic excavators sold are made by Hitachi. In addition to construction equipment for infrastructure projects, a core segment of Tata Hitachi’s business is equipment solutions for the mining industry. Products include mining excavators, wheel loaders and dump trucks.

The ZAXIS series of 45–87-ton excavators offers high operational capacity to work uninterrupted around the clock, while the hallmarks of its mining class EX series, from 100–800 tons, are high on productivity and low on operating costs.

In 2019, Hitachi Construction Machinery in Japan unveiled its next-generation EX-7 series of mining excavators. Along with the safety and productivity that is characteristic of all its machinery, this new range also offers IoT capabilities.

In India, Tata Hitachi has also started promoting its new ZW series wheel loader, from 5–10-ton payloads.

As the company – like every other in the industry – faces increasing competition from Chinese equipment manufacturers, Sandeep says that ensuring fair, transparent and customer-oriented policies are at the core of today’s business and the basic value of the company. “We are really concentrating on the importance of offering quality product solutions to our customers and ensuring that they are well looked after. Our customers should be first in our minds,” he explains.

“We know that there are three categories of customer focus in an organisation: customer focused, customer centric and customer driven,” Sandeep continues. When he first joined in 2015, he felt the company was at the first stage: customer focused. “Although we were looking at the customer, with most of the decisions we were making, we were inward looking: putting the company first,” he admits.

The years since he started have seen a progression to the next stage, the customer-centric phase. This is where he believes the company is currently placed. “We now look at the customer at the very first stage of most decisions we make,” he says.

“We now look at the customer at the very first stage with most of the decisions we make.”

“That’s the culture we have started working on and I’m happy to say that, to a large extent, it’s going as per the plan. In this phase, the quality of the machine is very important, as is competitive pricing and our response levels to our customers,” Sandeep explains. “But our own actions, such as working as a team, are just as important. In everything we do, we keep in mind what needs to be done to maintain this current level and achieve our next goal,” he explains.

He believes the company will remain in this current phase for another three to four years. “Then we’ll be ready to go into the customer-driven stage,” he explains. While reaching this final stage requires significant investment, the rewards are evident and once done will place Tata Hitachi in a select group.

“Very few organisations are customer driven, where all the decisions are made with the customer in mind. It’s a basic value that we are working towards and one that we will not compromise on,” he says.Sandeep emphasises that, for Tata Hitachi, there are various ways to define ‘customer’, and the term is not limited to the end-user who operates its machinery in an infrastructure or mining context. “Our customers are also our vendors, our dealers, or even the other divisions in our company,” he explains.

It’s only natural that, as he strives to place the customer first, the company’s relationship with its vendors and dealers has also found itself under the spotlight, especially in the wake of the industry downturn earlier this decade. “There was a very big gap of four years, where we had issues in terms of trust between the vendors and ourselves because when the market goes down, their business also suffers,” he explains. “It was very difficult to conduct business during this time.”

Steps were taken to rebuild the damaged relationships. Improved communication was the first. “We held dealer and vendor conferences. These were forums where we could open lines of communication, where we could listen to them,” he says. “These are crucial partners for us: dealers are our face to the market and take care of our customers, while the vendors look after our back end and supply the components that allow us to manufacture our equipment.”

That the company has been able to recover from a not-so-good four years “really shows the strength and value of the company”, Sandeep affirms. But more than mend broken partnerships, these renewed relations are also a driving force behind Tata Hitachi’s current success in the marketplace.

“We have worked a lot in terms of developing our dealer policies. We have a very clear evaluation system and a separate dealer development cell in the organisation, which is devoted to dealer infrastructure, manpower systems and profitability,” he explains.

Other “softer areas”, as Sandeep refers to them, where Tata Hitachi provides dealer response and support, include sales and marketing activities, customer care, improving staff skill levels and sales support.

“It’s an area that is very carefully planned out and, today, our dealers are doing very well. They’re strengthening their infrastructure and developing skilled manpower,” he continues. “We also have very clear policies regarding vendors, in terms of our supply chain and improving efficiency, as well as hand-holding them to improve their product quality in addition to providing training on processes to ensure timely delivery,” he says.

“Today, our dealers are doing very well. They’re strengthening their infrastructure and developing skilled manpower.”

“We expose our vendors and dealers to the latest technology, introduce them to different industries, showcase to them how we can improve the quality of our components and how we can reduce costs and improve efficiency,” he says.

Despite a two-fold increase in production, Sandeep explains that the company has also made a conscious decision to consolidate its vendor base. “This has allowed them to benefit from a larger slice of revenue, as well as increased profitability and scale of operation,” he says. Currently, he estimates that 80% of its business is generated thanks to 60 key suppliers.

The company has increased focus on additional lines of business – the setting up of Re-Man Center at Kharagpur for the remanufacturing of components, the online sale of spare parts and the foray into the used equipment business. “Our strategy is very clear and, today, I am proud to say that it is an area where we are doing very well,” he continues.

Although in a much healthier place than when he was first appointed Managing Director four years ago, Sandeep believes the construction equipment industry still has a way to go before it reaches its full potential. “What I currently see happening in India is that, unlike a large industry such as commercial vehicles, ours is one that is growing and still maturing,” he explains. As a result, he says that he has witnessed too many occasions when “we compromise on basic values when we deal with our customers”.

“When we are in a phase of development, we should not be compromising on these. At Tata Hitachi, we practise very fair, transparent and customer-oriented policies to ensure that we offer quality product solutions and look after our customers well,” he concludes.

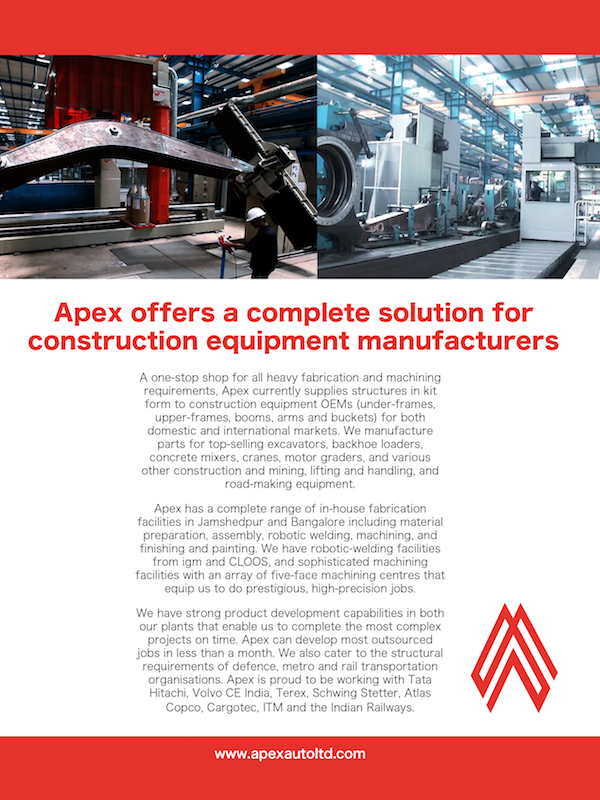

Proudly supported by: