A civil engineer with an MBA, C-suite experience and more than three decades of experience in the infrastructure sector and a company that has built its name as one of India’s largest sugar manufacturers seems like an unusual fit. But there’s much more to Triveni Engineering & Industries than sugar, even if that’s what it was founded on nearly 100 years ago in 1932.

Alongside sugar and alcohol, power transmission, defense and water solutions now round out the Uttar Pradesh-based company’s five business divisions. It’s the latter that Kamal Verma, who has worked for multinationals in countries including the United States and France, heads up as CEO – Water Business Group.

Triveni’s entrance into the water and wastewater treatment sector came in 1997 to deliver innovative, end-to-end water recycling solutions, although it had been manufacturing wastewater treatment equipment since the 1980s. When Verma joined in 2018, however, the division was in the red.

“The first target was to turn that around, into the green,” he tells The CEO Magazine.

“One of my achievements is turning around the company and consistently maintaining profitability.”

The company was facing a number of challenges in terms of business acquisition, execution delays and profitability. With his extensive leadership experience, Verma wasted no time reorganizing or, as he says, “restructuring some of the departments”.

Following that, there was a push into new areas where he spotted gaps in the market, particularly water treatment, wastewater treatment, tertiary treatment, recycle and reuse, and zero-liquid discharge.

“My other idea was to internationalize the business,” he says.

Along with India, projects in the Maldives, Bangladesh, Uzbekistan, Serbia, Croatia, Egypt and Nepal have followed. Before too long, the company was exactly where Verma wanted it to be: in the green.

“One of my achievements is turning around the company and consistently maintaining profitability,” he reveals. “We have been profitable since I joined the company.”

The bottom line

As CEO, Verma’s responsibility is end-to-end across the business, with the bottom line being profit and loss.

“Typically, our clients are government or public sector entities,” he says. “We design ourselves, we supply, we execute the jobs and then do the operation and maintenance of the water treatment projects.”

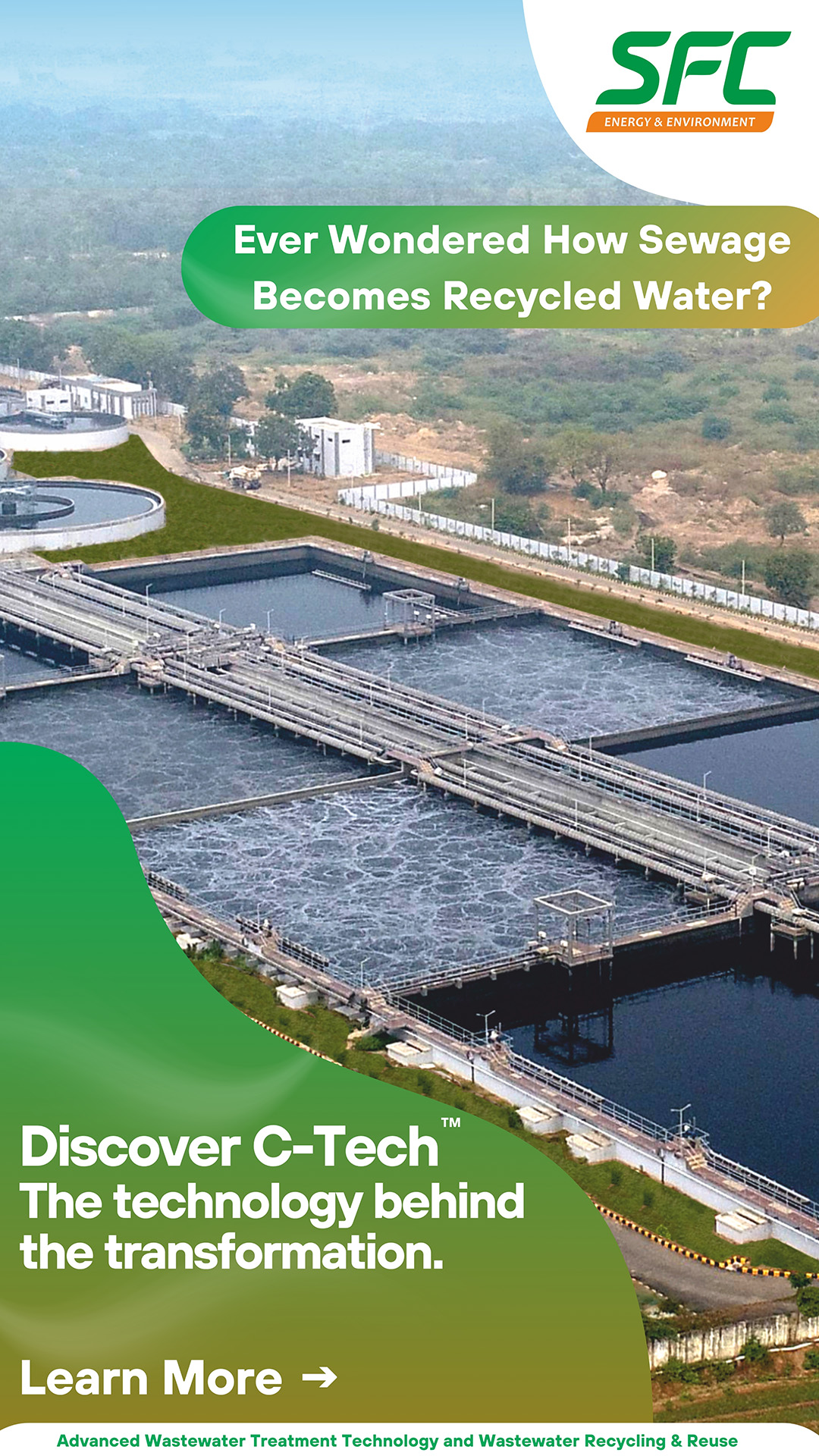

Notable projects include a wastewater treatment plant in Pali to treat wastewater from over 450 industrial units, along with an integrated sewage management system in Mathura, designed to intercept and treat sewage before it enters the Yamuna River. The project includes a 15-year operations and maintenance commitment.

Sweet success

When Triveni Engineering & Industries was founded in 1932, it was under the name The Ganga Sugar Corporation. After becoming Gangeshwar in 1973, the company took on its current name in 2000 after it merged with Triveni Engineering & Industries.

Today, it operates eight sugar mills in Uttar Pradesh with a combined crushing capacity of 70,500 metric tons of cane per day to supply various grades of sugar, including pharmaceutical, to domestic and international markets.

The company generates renewable energy from by-products of its sugar manufacturing and operates three distilleries for ethanol production. Its market cap is US$3 billion and it employs over 7,000 people full-time.

On both projects, Triveni is the co-investor with the government in what is called a hybrid annuity model for public–private partnerships. Another way the company works with the public sector is through the Confederation of Indian Industry-Triveni Water Institute, established in 2008 to bring together government, industry and civil society to address water-related issues holistically.

“We fund the organization so it can undertake a lot of government work free of cost, like conducting various water audits and water surveys – basically anything that benefits the life of the general population, whether it’s a rural or urban area, so that every household can access pure water,” Verma says.

The in-house advantage

Triveni’s in-house capabilities are what sets it apart in a highly competitive field, according to Verma.

“We do everything in-house,” he says, explaining that this includes cost, design and engineering.

Significant improvements in operational efficiency since he joined have enabled the business to take on these substantial challenges, he adds.

“The efficiency of people, human resources and process management are key. We have written our own operating procedure for streamlining and operating processes with clear goals and expectations – from both our people and the project.”

Of course, automation has also been embraced.

“We use technology wherever possible,” he confirms.

It’s something that wouldn’t be possible without core partners and over 800 vendors. Looking forward, Verma predicts that recycling and reuse are sectors from where growth will come.

“We’re early movers and we have advantages,” he says.

“I’m fully committed to growing the business.”

Currently, Triveni has several projects in the pipeline, with many more in its sights.

“The business is growing in the Indian market, and this has the potential to be replicated in other South-East Asian countries as well,” he points out. “There’s also a lot of potential in the Gulf countries and Eastern Europe.”

Verma may have met every challenge set when he started, but his motivation is still as strong as that first day he started.

“I am fully committed to continuing to provide excellence in terms of technology, quality of the plant and meeting the required parameters,” he says. “I’m able to meet clients and maintain key relationships with clients and partners.

“I’m fully committed to growing the business.”