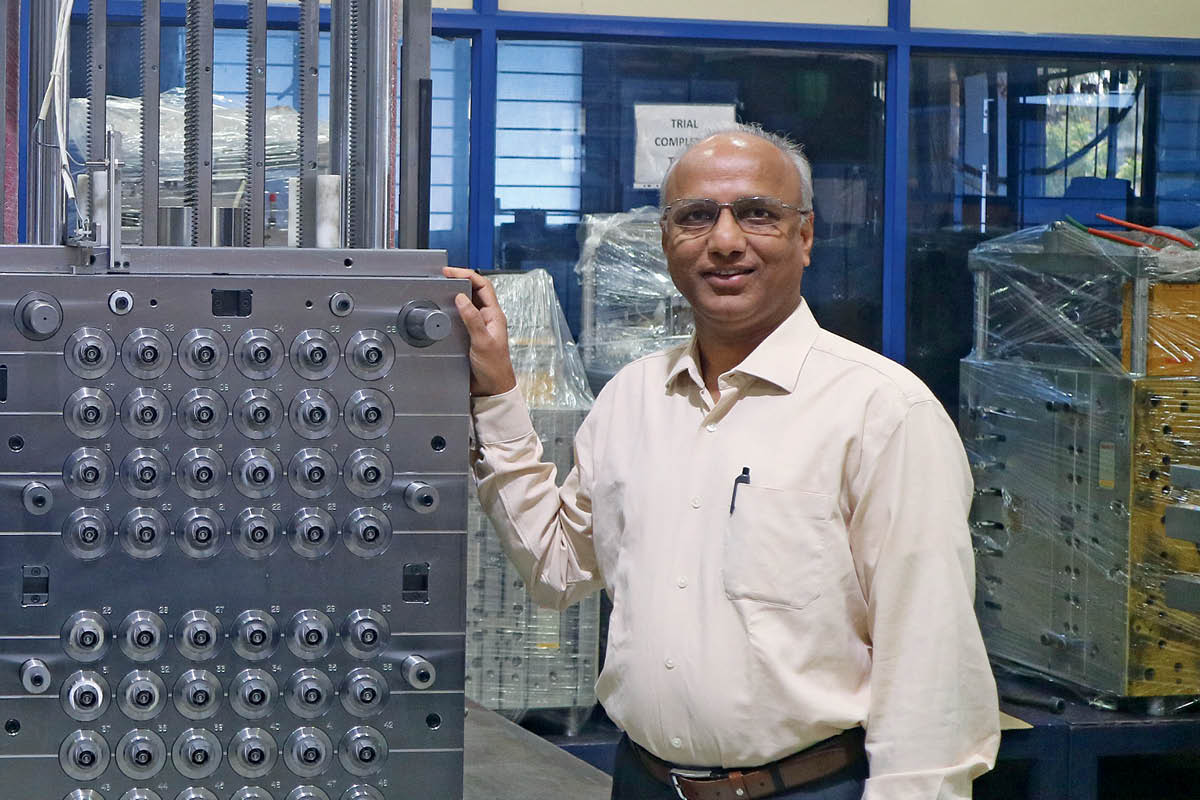

Since the day he graduated, Dayanand Reddy knew he wanted to run his own business. He always longed to create employment for the people of his region. Today, this mechanical engineer has realised his dream. As the Managing Director of Vasantha Tool Crafts Pvt Ltd, he employs more than 500 people to design and manufacture plastic injection moulds to multiple industries in a global market.

Not bad for a business he launched in 1989 with just a few rudimentary machines and a workforce of 10. “I come from a humble and rural background and saw a huge need for employment is growing up,” Dayanand explains.

Quality, quality, quality, it’s our mantra.

“I knew I could provide jobs for people of my region. “Some of our employees have celebrated up to 28 years with us now and about 50% have spent more than 10 years in the company. We do take care of them and they have contributed a lot towards the growth of Vasantha.”

Located in Hyderabad and boasting five plants in the region, Vasantha has designed and manufactured more than 3,000 high-precision, high cavitation plastic injection moulds to create thousands of products used in the personal care, food and beverage, healthcare, household, electrical and engineering sectors across more than 40 countries.

In October last year, Vasantha announced its plans to build a new mould-making facility in Austria, which will have the capability to design, manufacture, assemble and test its own moulds to support the company’s growth in Europe, with operations due to commence by 2021.

There are also plans for a service shop in United States, intended to provide after sales support. The company’s in-house services include product design, prototyping, mould design, manufacturing, testing for pilot, and series production moulds.

Its market segment is 80% for FMCG packaging and the balance includes OTC, Medical and Electrical. “My family ventured into a small business requiring a little bit of mechanical engineering and maybe that’s the reason I veered into this activity,” Dayanand explains.

“I did my post-graduation in tool design and manufacture, which is why I have carefully selected my own field, injection moulds. I knew it was going to be an expensive proposition, which meant I couldn’t start in a big way, but mould-making is a niche market that gives you lot of satisfaction because it deals with precision engineering.”

This niche market has led Vasantha to introduce many industry firsts in technology and manufacturing to become a front runner, producing moulds for wide range of products.

These products range from caps to toothbrushes, tubs to disposable shaving products, and inhaler mouthpieces to items for the electrical switch gear industry.

Clients include Unilever, L’Oréal, Colgate, Reckitt Benckiser, GSK, Emami, Dabur and many more in the geographies of Asia, Africa, the Middle East, Europe, South America and the US.

“Our technology has allowed us to do things never done before in India,” Dayanand says. “We imported our first CNC (Computer Numerically Controlled) machine in 1996 from Switzerland, which was quite difficult because in those days there was a customs duty as high as 50% and that machine made all the difference.

We can attribute all our growth to that kind of machinery, which took us to the next level, and then the next, and the next. “Because mould making requires a high investment, not everybody can do it successfully,” he continues.

“It’s not a mass production industry, every job is different. Today someone may come to us with item A for which we have to make a mould, then tomorrow it might be item B. It is always challenging. It’s not like forging or general casting where the tolerance or accuracy levels are wider. Here, we speak in terms of microns, a 1,000th part of a millimetre.”

Vasantha introduced a state-of-the-art robotic cell into manufacturing in the year 2012 and then another one after four years. These cells operate 12 machines which Dayanand says not only gives premium quality but also ensures consistency.

“This helped us to manufacture high-precision moulds indigenously, which erstwhile were needed to be imported at a very high cost and longer lead times. Due to this, Vasantha is often consulted by various customers to assist in their packaging R&D activities.

This state-of-the-art equipment and vast experience helps us to offer much faster delivery schedules compared to any global competitor. “Quality, quality, quality is our mantra,” Dayanand says.

“For the past three decades, we have had a reputation for quality, always giving a little more value than what the customer actually pays for. We follow good manufacturing practices including high cleanliness of the shop floors and offices. Be it on delivery schedule or on the cycle time – if we can deliver the mould a week faster, while running at a cycle time of a couple of seconds less with all this technology we have invested in, it’s worth it.”

Proudly supported by: