Jack Goh is undeniably a man comfortable with change. In fact, he thrives on it. Nothing makes him happier than watching new products, all boasting the best in sensor intelligence, roll endlessly off his production line.

But, among a rapidly changing environment, he is simple at heart. The Managing Director of SICK Product Center Asia admits that his favourite thing about Singapore is, “Simple chicken rice,” he laughs. “Yes, I love the diversity of food in Singapore, but I’m a man with simple tastes. And chicken rice takes me back to my roots.

I come from a poor family and if we had money we would eat out, but even then, we’d eat something cheap. And that was chicken rice. Very basic.”

While the ingredients for Singapore’s national dish have remained unchanged for more than half a century, the elements making up Jack’s digital world at Singapore’s SICK Regional Product Center are changing rapidly.

It’s in the midst of Industry 4.0, and there’s no escaping the disruption the industry faces.

Named after its founder, German inventor Erwin Sick, the 72-year-old company is a global leader in the manufacture of sensors and sensor solutions for industrial applications.

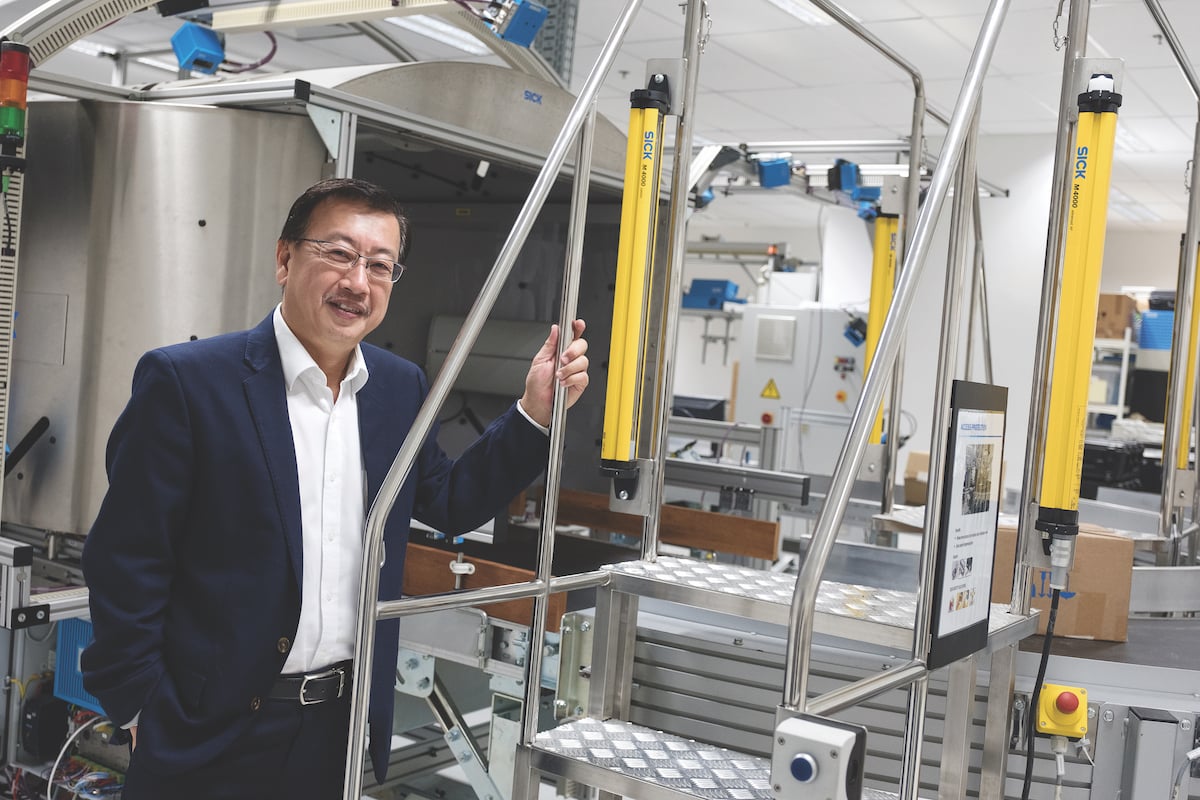

SICK sensors are widely used in industries to create safe, reliable and efficient control processes to protect, inspect and monitor.

Headquartered in Waldkirch, Germany, the company employs nearly 9,000 people in 50 global subsidiaries, most of them sales offices.

SICK has only three regional product centres. Jack heads the Asian centre, made up of the R&D facility in Sembawang, Singapore, and the production site in Johor, Malaysia.

The other two regional centres are in Europe (where R&D is conducted in Germany and production in Hungary), and in the US (in Minnesota).

“Our key focus in Singapore is to design, develop and produce products for the local market in Asia. However, we also manufacture SICK’s core products for global export,” Jack explains.

“We have three levels in terms of performance and cost. At the lowest level is our core product, the basic sensor produced at a very high volume. In the middle, we have the prime product, slightly higher in performance but produced at a lower volume.

Then right at the top, we have what we call ‘the pro’, the more professional products, very high in performance and cost, but produced in low quantity.”

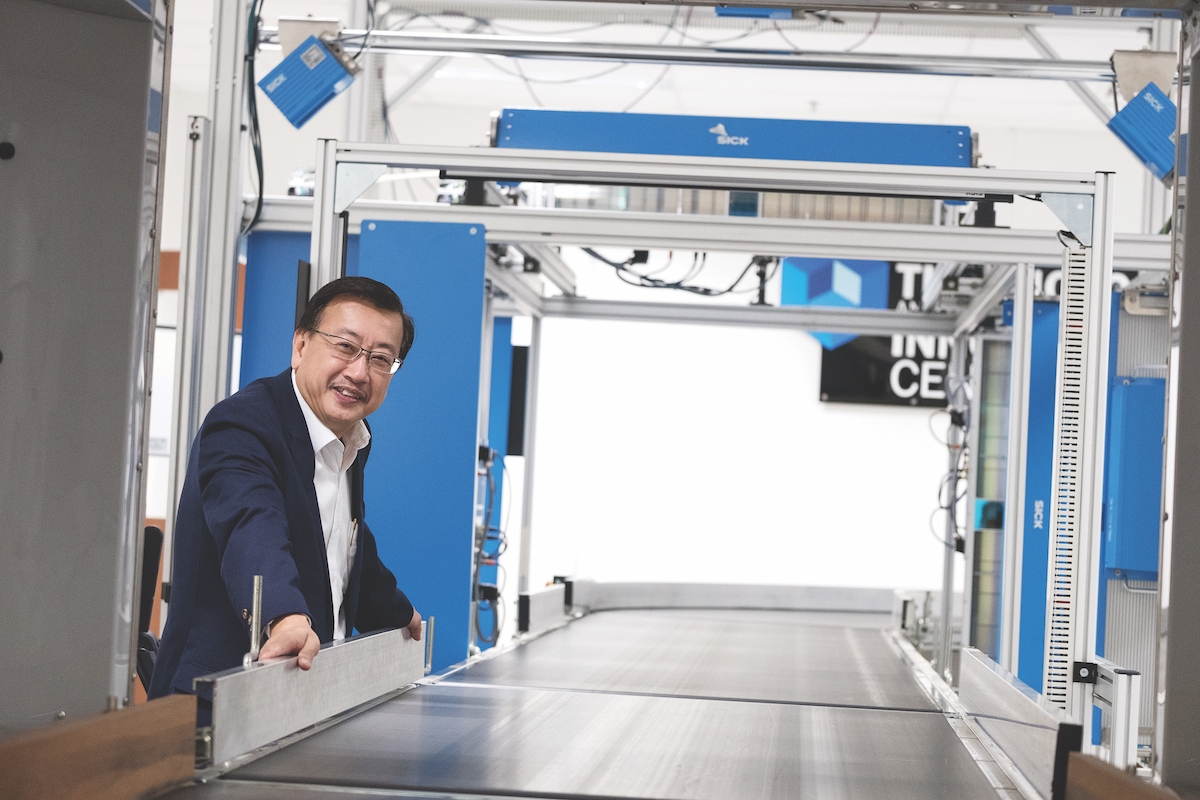

Renowned particularly for its laser scanners used in security, ports and robotics, the company’s product portfolio includes photoelectric sensors, light grids, inductive, capacitive and magnetic sensors, opto-electronic protective devices, vision sensors, detection, ranging and identification solutions such as barcode scanners, and RFID readers, analysers for gas and liquid analysis and gas flow measuring devices.

Major clients using SICK technology for their logistics hubs include Amazon, DHL and FedEx, while about 75% of the world’s international airports use SICK sensors in hundreds of applications.

SICK laser scanners help prevent airport ground vehicles from colliding with airport buildings, while automated light grids are used for security at passenger boarding bridges and security door systems.

SICK technology is also used for automated bag drop-off, size detection, monitoring the park position of aircraft, measuring the height of the passenger boarding bridge, measuring freight objects and opening the swing doors at the customs exit.

When German headquarters recognised a high demand in Asia for SICK’s core products, the company established Singapore’s R&D facility in 2009, with the manufacturing facility following a year later in Malaysia.

Jack joined the Singapore company when it started, knowing full well he had a monumental task ahead in building the brand and getting cost-effective products into the market.

“I was appointed general manager with three engineers reporting to me. While SICK was well known globally as the German quality sensor company, we had to build the business from zero,” Jack remembers.

“At the same time, our R&D team were inventing new products to serve different functions and I’m sure the number of products we put on the market, plus their excellent quality, helped develop our brand in Asia.”

During its first five years of operation, the Singapore office was under the close scrutiny of headquarters in Germany, with both working jointly to produce and successfully sell more than 13 new product families. Technologies developed included optical electronic, inductive and magnetic, RFID and laser sensing for industrial and logistic applications.

Today, Jack leads a team of 360 people, working in production, design, sales, procurement and product management, with 25 product families, offering around 3,500 different products.“We produce up to five million units a year, with more than 50% of them heading to local markets and the rest to Europe and the US,” Jack says.

“Our German headquarters couldn’t compete cost-effectively if we had to do the R&D and manufacturing in Europe. China is our key customer and we sell very well in that market. The Chinese want the German engineering and quality, but the only way we can get them to buy our product is to keep costs down and we do that by developing and manufacturing locally.”

Another cost-effective strategy is SICK’s commitment to employing local people, at all levels of staffing and management, and sourcing resources and materials from the local region.

“We use the strategy of ‘local for local’,” Jack explains. “In terms of talent, competence and human resources, all of it is sourced locally. While SICK provided intensive training and transferred sensor knowledge to local staff, over the years our local team has gained the competence to develop and build exciting products.

“We use the strategy of ‘local for local’. In terms of talent, competence and human resources, all of it is sourced locally.”

The positive results today show that relying on local competence, employing people like me, works. We are leading globally with local people because we trust in local competency.”

To ensure the quality of the products are maintained to the exceptionally high German standards, there are no

shortcuts with quality control, starting from the very beginning at the design stage.

“A strict quality code is built into the production line,” Jack explains. “While the product concept and design may come from Singapore, we align with Germany so the design is in sync with the global product portfolio. Everything is streamlined. It’s a perfect blend.

“By the end of the production process, the quality assurance effort is quite small. It is just a matter of verification and checking to ensure that everything complies.”

Jack attributes the continuing success of the business over seven decades to the original pioneering spirit of Erwin Sick. The company is still family-owned, with Erwin’s wife Gisela an Honorary Chairperson of SICK’s supervisory board, and his daughter Renate Sick-Glaser and grandson Sebastian Glaser as members of the supervisory board.

“Erwin was an inventor and that legacy is carried on throughout our company,” Jack says. “We don’t just speak the language of innovation, we show it by investing 10% of our revenue back into research and development. It’s our target every year.”

Jack also believes the company’s dedication to developing and producing only sensors is another factor contributing to its market leadership, and goes on to explain the significance of the company’s logo.

“You’ll see underneath our logo, ‘SICK’, are the words ‘Sensor Intelligence.’, with a period,” he says. “That period is there for a reason. It represents that as a company, we are focused solely on sensor intelligence. We don’t diversify into other fields like our competitors.

“We don’t diversify into other fields like our competitors. There is a danger to that.”

“There is a danger to that. You step into territories that are dominated by your existing clients. For example, some sensor companies have started to make robots. But if we started making robots, we’d be competing with our own clients making robots who use our sensors. They wouldn’t want our business if we did that.”

SICK’s mission boasts three mantras: Independence, Innovation and Leadership. While innovation is clearly what launched the entire vision for the company, independence and leadership evolved along the way.

“It’s important for us to remain financially independent. It gives us the freedom to define our own direction, design a system that is completely independent and not reliant on others. We take pride in being self-sufficient.

“As far as leadership goes, we lead by example,” Jack adds. “We build leaders within the organisation who have strategic views and a vision for what business and technology will look like in the future. We need that to establish our market position. That’s an important philosophy of our leadership strategy.”

Jack’s own leadership style was developed on the job. He learned the basics of his trade from an engineering diploma at a polytechnic, but from then on it was all hands-on experience.

“I learned from hard knocks, growing from the ground level up,” he says, but with a laugh. “My first job was working in the production area of Dorma, which produced door technology systems. Then I went to John While Springs where I learned the technology while working my way up to management.”

Jack admits that while his attraction to SICK was very much due to the company’s flawless technology, it was the company’s culture which appealed even more.

“I liked the German mindset, the way they took care of their people,” he says. “That is something very important to me, because I have the same philosophy. Since I started the company here in Singapore from scratch, I was able to design and control the culture with that same care.”

“I liked the German mindset, the way they took care of their people.”

Jack admits another attraction was the creativity of a company constantly innovating and producing new products. He’s inspired by the fact that no matter how many products his centre produces, there are more, different ones, ready to go or in the pipeline.

“I like to create and see new things and SICK is constantly putting new products on the market. I also like it that the company can determine its own future by continually innovating.

“Despite being in Asia, we are not too concerned by local competition,” he adds. “All our sensors are equipped with a unique and very advanced ASIC, an integrated locked circuit system, with a lot of functions embedded. So, while the competition can copy their physical aspects, they can’t copy the logic embedded inside our integrated circuits.”

One of the first products produced in Singapore about eight years ago was the mini optical sensor, which converts light rays into an electronic signal. The sensors are used widely for a variety of functions, including as an electronic optical switch for presence detention; sensing an object in a light beam; or detecting the distance, absence, or presence of an object.

Another common application is using the optical sensors to adjust screen brightness on smartphones.

“We started from a zero-product base and now sell more than a million of those mini optical sensors a year. I think that’s really the satisfaction I get. Building a company from scratch, watching it grow through different stages, from developing funds to developing products, and organising the structure to where it is today.

“But what is really interesting is that it doesn’t end there. Our organisation is still changing and always will. Because of digitalisation, we are constantly evolving and redefining ourselves, training and updating our people. It’s wonderful to see an organisation positively motivating its employees who are also very engaged and want to be a part of it.”

A passionate inventor

Dr Erwin Sick was a passionate inventor whose idea to combine optics and electronics harnessed the power of human vision to monitor machines and emissions. He began his professional career with an apprenticeship in optometry before attending the Institute of Optics and Precision Mechanics in Göttingen.

In 1932, he joined the optical department of Siemens & Halske, a company producing electrical devices. After his department closed, he was moved to the lab where he began producing sensors by combining electrical devices with binoculars and cameras.

During World War II, he headed the Laboratory of Optical Works at A&C Steinheil & Söhne in Munich before setting up his own company in old barracks in Vaterstetten and receiving a license to practise as an engineer. Sick AG was founded in 1946.

Five years later, at the German Inventors and Innovations Fair, Erwin presented his first finished wooden model of a photoelectric sensor and was awarded a certificate for ‘creative performance’.

A vital breakthrough came the year after when he introduced the accident prevention light curtain at the Hanover Trade Fair. Orders flowed in, enabling Erwin to expand and move to Waldkirch. In 1960, he founded the Institute for Automation for developing optoelectronic devices for industrial applications.

He was awarded an honorary doctorate in engineering in 1980 and received the gold Rudolf Diesel Medal for his numerous inventions in 1982. Erwin died six years later,

at the age of 79.

SICK’s loyalty and motivation extends to its suppliers, resulting in long-term partnerships with Lucky Plastic Mould, Focuz Manufacturing, Kian Soon Mechanical Components and Finecables Enterprise. “Most of them have been with us from day one,” Jack reveals.

“We have a very good and close relationship with them and they are important to us. SICK is not a company that takes advantage of its suppliers; we view them as our business partners and encourage a win-win relationship.

“At times, if some of our suppliers encounter financial difficulties, we do what we can to support them so they are able to continue their operations. Then, in turn, because our relationship is so good, when there’s something we require urgently, they are willing to hand-carry a part on the plane to deliver it to us. We treat them well and they are there for us.”

Jack understands the future lies with young employees fixated on the latest technology and driven by digitalisation, and he’s immensely proud of the comprehensive and generous training program the company offers. Recruits are sourced from local institutions and offered various avenues to launch their careers with SICK.

“Every year, we have about 20-30 students completing internships with our engineers,” he says. “We have a program where we send selected students from polytechnics to study in Germany for about four years. We pay their education, accommodation and allowances, and during their holidays they intern at headquarters to learn that special German mindset.

But we also fly them home, back to Singapore, for internships of about three months so they can see their families and learn the local business. Then, when their studies are completed, they come back to work for us.

“There are also other students who are good but are unable, or prefer not to go overseas. So, we sponsor them to study in Singapore universities, giving them two options. They can study full-time and do internships with the company during the holidays, or work full-time with us and study part-time.

The latter gives them the option of earning some income so they get the best of both worlds, studying the theory at night and applying it to their jobs during the day.”

Company decisions are made on the parameters of Industry 4.0, the term first acknowledged by Bosch at the 2011 Hannover Trade Fair. The trend recognises automation and data exchange in manufacturing technologies, with Smart factories a prerequisite and sensors the core, allowing machines and people to exchange information at any time, anywhere.

“It’s a huge shift, this move to digitalisation,” Jack says. “We are designing more advanced autonomous intelligence into the sensor, which will give it the ability to make decisions.

There will also be sensors with predictive ability enabling them to tell the engineers they need some support, that a part is becoming weak and needs replacement. We are also looking at IO (input and output) connectivity and wireless connections to make sensors more versatile and flexible.

“Everything is so much faster and the strength we have is not just in recognising a sense for change in technology and innovation, but having the foresight to restructure the organisation into a digital culture so all of us can adapt to change quickly and effectively.”

Jack, the father of three sons, none of whom are in the technology industry, credits his wife with the best piece of advice he’s received.

“She’s always telling me not to keep myself too busy,” he says. “She tells me to take a step or two back to get a more balanced view of things. I do that every morning by walking about six kilometres around my estate. It gets me outside my working environment to clear any deadlocks I may have in my head.

It helps me get a fresh perspective, to look at things differently.

It’s comforting in this rapidly changing world of technology and digitalisation where the only constant is change.” As comforting as chicken rice? “Oh, no,” he laughs. “Chicken rice. That’s different. That’s food for the heart!”