Leading a major multinational organization clearly requires a unique skill set, yet such a high level of business expertise is difficult to learn from a book or in a classroom. There’s no substitute for on-the-job experience.

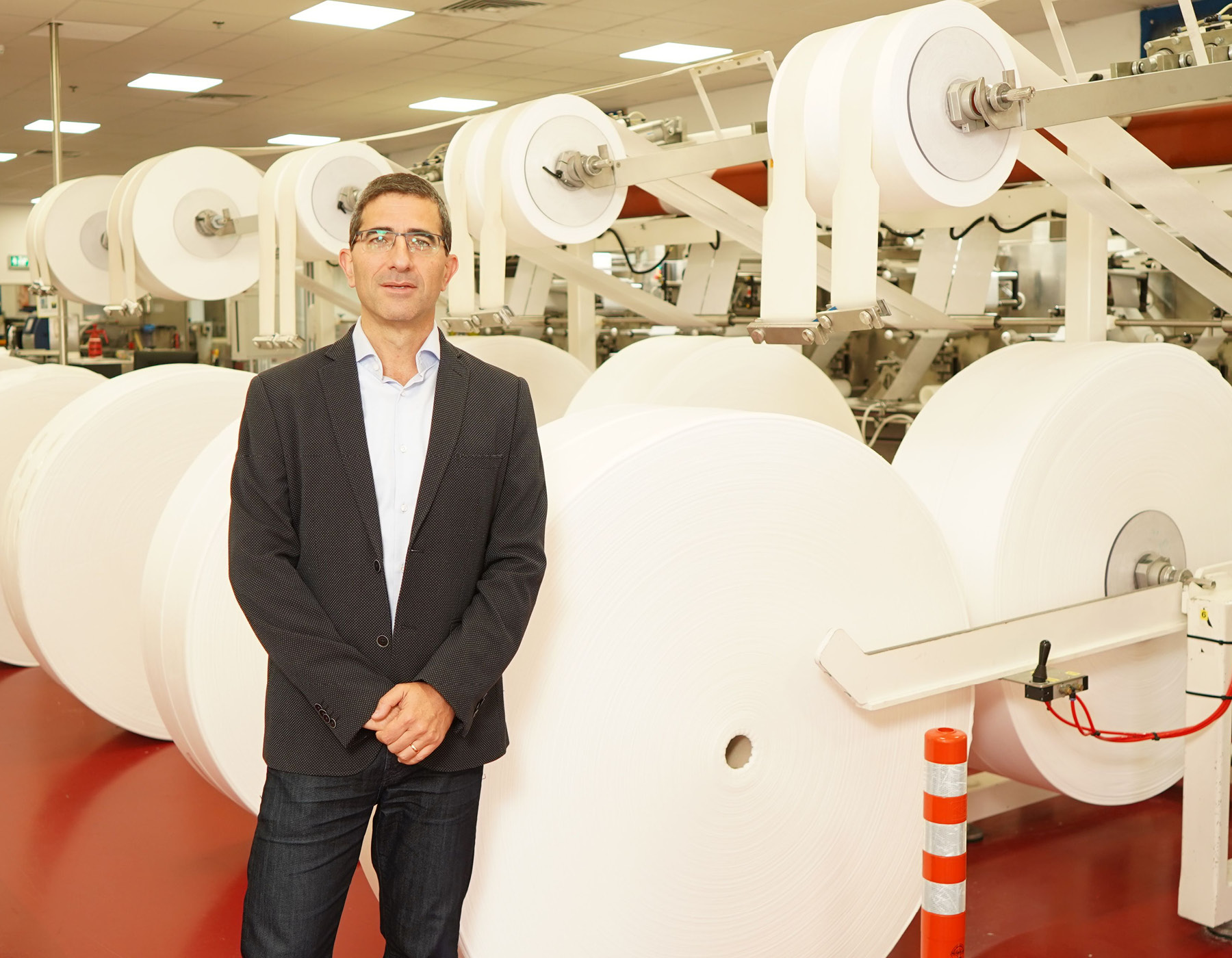

After many years of serving as either Deputy CEO or CFO for large billion-dollar companies, Jacob Heen felt it was time for him to take the lead of a business.

“When Albaad Massuot Yitzhak approached me and offered me this job, for me, it answered exactly what I was looking for,” he explains.

Now CEO of Albaad Massuot Yitzhak, one of the largest manufacturers of wet wipes and feminine hygiene products in the world, Heen has found the role a perfect fit. In one of his first projects as CEO, he successfully implemented a rights issue of shares in order to strengthen the balance sheet.

I really like to work in global companies because the opportunities are much wider compared to a local company.

“I really like to work in global companies because the opportunities are much wider compared to a local company. I believe in public companies because they’re more transparent, usually much more professional and the needs of the main shareholders and the public are well-balanced,” explains Heen.

In its financial results for the first quarter, ending 31 March 2023, the company’s share price rose by more than 20 percent. “Investors appreciate and believe in our new strategy,” he comments on the result. “We are fully committed to continuing to create value for our customers and shareholders.”

Growth plan

With two core business areas, Albaad has built a clear plan for future growth. The business is well-developed in the wet wipes market and maintains a strong presence in the feminine hygiene division, where more than 80 percent of clients are located in the United States (the remaining 20 percent are in Europe).

“This means that we are producing the fabric in two sites with two different technologies: the spunlace and the hydrofine, which is a biodegradable, plastic-free material,” he says.

In the wet wipes sector, Heen is looking to focus on Europe for growth due to the close physical distance of its customers from its factories and the ability to benefit from being a fully integrated company.

We enjoy continued growth in sales, together with reducing the cost of materials and shipments, along with better automation in our facilities. These are the keys to success.

In the tampons division, the goal is to strengthen the company’s position, even in the United States market, and with specific customers in Europe as well. “This gives us the opportunity to lead in both markets,” Heen explains.

“The main focus is to strengthen our financial opportunity and financial position – the fact that we can bring back the working capital from the United States market to Europe helps us to strengthen the balance sheet as well.”

Measuring success

Each enterprise has areas they want to improve to ensure their business remains robust. For Heen, the central goal this year is to increase profit levels, achieve growth and strengthen the positioning of the business.

Conventional measures of success, including factors like net debt-to-EBITDA and balance sheet ratio, are other important aspects for the business to focus on.

“We enjoy continued growth in sales, together with reducing the cost of materials and shipments, and better automation in our facilities. These are the keys to success,” he adds.

I believe in public companies because they’re more transparent, usually much more professional and the needs of the main shareholders and the public are well-balanced.

Efforts to add automation across its factories is another element of the strategy going forward. However, automation by itself is not enough, with a solid platform and switched-on managers also being vital components. This combination is especially important to make sure that all KPIs, IT and the business intelligence systems are moving in the same direction.

“This means that we can be competitive compared to third parties and other suppliers,” he says. “I would like us to be much more competitive compared to third-party purchasing.”

Pandemic challenges

Few companies have been left untouched by the repercussions of the global COVID-19 pandemic, but the real test of corporate resilience is how organizations have dealt with the shifting economic climate. For Albaad, focusing on operational excellence across the business has played an essential role in thriving in the post-pandemic era.

The key is to be more efficient and to use the fully integrated facilities that we have in the fabric that we are selling.

“The key is to be more efficient and to use the fully integrated facilities that we have in the fabric we’re selling. We can be much closer to the demand of the customers and the quality is high. That’s the key to succeed in the coming years,” he adds.

Due to the impact of the pandemic, transportation costs rose exponentially. Heen points to the example of the cost of a single container from Asia priced at around US$2,000 before the pandemic, peaking at more than US$17,000 amid the global crisis. Prices have since come down to around US$3,000, but Heen and his team have worked hard to ensure transportation costs are optimized.

Innovation first

Innovation is actively built into the production process at Albaad. The acquisition of a Spanish wet wipes manufacturer and the decision to invest over US$54 million in a new plastic-free non-woven production line in Israel are yet two more representations of the company’s commitment toward sustainability.

In addition, Albaad constantly invests in promoting the safety, health and wellbeing of its people, who the company considers its most important asset and strength. “At Albaad, we’re more committed than ever to do our part in sustainable business, while driving value for our stakeholders and the environment,” Heen says.

By establishing a number of sites near customers, the business has become very well positioned in Europe. In practice, this means having sites across Central Europe, Eastern Europe and Western Europe, including in Germany, Spain and Poland.

“At the one end, we can serve with a cheaper cost and at the other end, if we need to support other locations – for example, if we have more demand for a specific customer in Europe, we can facilitate them through our factories in Poland or Israel. This gives us more flexibility and opportunity,” he explains.