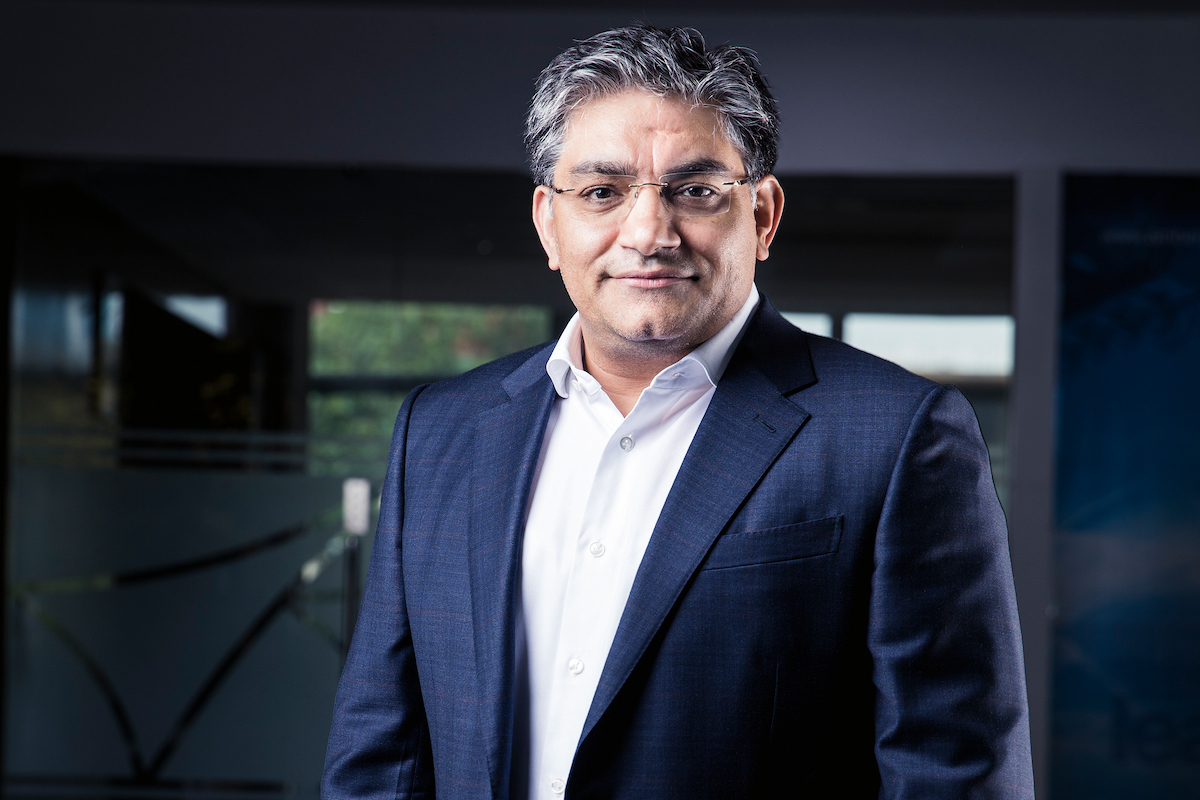

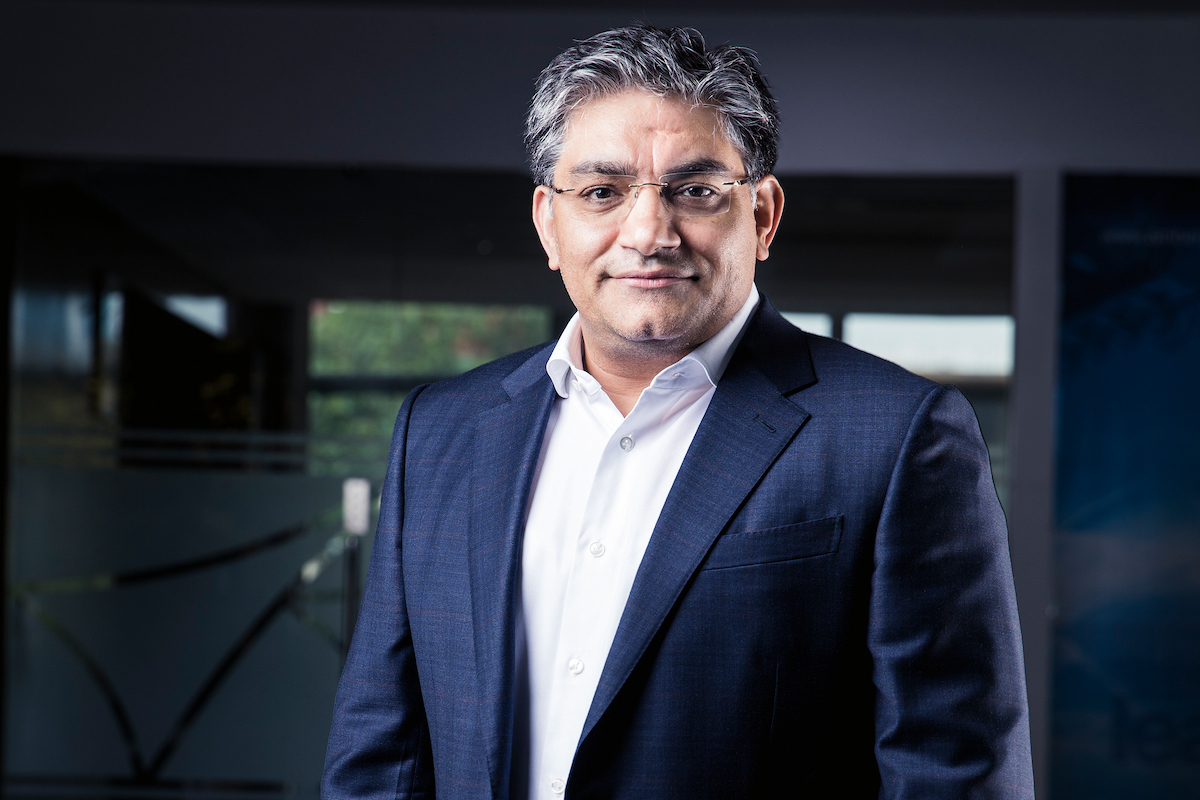

Twenty years ago, very few people in India had air conditioning in their homes, despite the fact most of the country has a tropical climate with extremely hot summers. Back then, Amber Enterprises India was manufacturing sheet metal components for tractors, light commercial vehicles and the telecommunications industry. CEO and Chair Jasbir Singh joined in 2000 after completing his Master of Business Administration.

He started out as a manager, but he quickly rose through the ranks to become General Manager before being promoted to Director, then to his current role. One key task Jasbir received shortly after joining was to help the company expand into new verticals. As part of those efforts, he found a market for Amber’s sheet metal parts in window-mounted air conditioners.

It was this discovery that led him to a realisation that would totally transform the company. “I saw a lot of opportunity in this space,” he recal. “Air conditioners had just started at that time in India, and only a few thousand units were being sold. This was one of the lowest penetration rates of any product in the country in the consumer durables category.”

Not only that, but India’s economy was developing in a way that convinced Jasbir that demand for aircooling products was only going to grow. “I was looking into the potential of India as a whole, and the population base was increasing, and so were per capita incomes, which brought with it an increasing desire for comfortable living,” he recalls.

Air conditioners had just started at that time in India, and only a few thousand units were being sold. This was one of the lowest penetration rates of any product in the country in the consumer durables category.

“On top of that, there was a government initiative to expand access to electricity to the whole country.” With such strong long-term fundamentals in place, Jasbir thought Amber Enterprises should produce not just components for air conditioners, but also entire units.

“I thought that this is one of the products that we should focus on as a finished good, and that’s how we started our finished goods offerings,” he explains. In 2003, Amber Enterprises became an original equipment manufacturer, producing air-conditioning units based on designs from customers. By 2010, the company had developed enough expertise and enough confidence in the strength of the market to start designing and building its own models.

“That’s when we started our journey towards being an original design manufacturer, where we started our research and development department and we started giving complete design solutions, end-to-end solutions, from the design stage to mass production for various customers. That’s how we have grown,” Jasbir says.

Today, Amber Enterprises serves many of the major players in the aircon and components space, including LG, Voltas, Hitachi and Daikin. The company also manufactures components for other consumer durables, including refrigerators, microwaves and washing machines, and it specialises in sheet metal, heat exchangers, motors, electrical and plastic injection moulding components, and vacuum forming for the automobile and metal ceiling industries.

Strong position

Since Jasbir’s initial transformation of the company in the 2000s, components production has remained a key part of Amber Enterprises’ business model. “As part of our journey, we saw that the air conditioners that are not being manufactured by us still need critical components like heat exchangers, motors, electronic printed circuit boards and sheet metal injection moulding,” Jasbir shares.

“So we decided we could be a good supplier if we diversified our geographic presence for the component section, and that’s what we did. Both the strategies of being an ODM player and an integrated player in components turned out to be very successful for us.

“We were a small company based out of a very cosy town in Punjab named Rajpura. It’s been an interesting journey over these 20-plus years.” Since then, Amber Enterprises has built nine more production facilities in six other locations across the country and drastically expanded its presence in the markets it serves. “Our market share today in India for room air conditioners is about 24 per cent in the manufacturing space,” Jasbir says.

“We have done three private equity rounds during our journey. We got the company listed successfully in January 2018, and we have also done four acquisitions.” The first of those acquisitions was in 2012, when Amber Enterprises bought PICL, an electrical motor manufacturing company. The second acquisition was of Iljin, an Indian manufacturer of printed circuit boards for home appliances, automobiles and other machines.

Next, the company bought Ever Electronics, another printed circuit boards producer. Most recently, it acquired Sidwal, which has expertise in producing air conditioners in the mobility space, meaning cooling devices for public transport. These takeovers strengthened the product offering capability and expanded the addressed market.

“We are the leading player in room air-conditioner application, and we are also the leading player in mobility applications and air-conditioner solutions for trains, metro coaches and buses,” Jasbir reveals. “In addition, we are the leading component manufacturing company in the space of consumer durables.”

Competitive advantage

The acquisition of Sidwal is part of one major strand of Jasbir’s growth strategy for Amber Enterprises: to continuously expand its product offerings and moving into new geographies, while increasing wallet share with existing customers.

“We will continue our focused approach in the room air-conditioner and the heating ventilation air-conditioning space,” he says. “Since the acquisition of Sidwal, we have expanded our addressable market into mobility applications. We’re expanding to new customers and growing our product offerings. That’s the strategy for growth moving forward, but overall, it’s about being a very focused player. We’ll do that while adhering to our core values of good intentions and hard work.”

The company is gearing up for global expansion as well and has already begun testing foreign markets. It has recently started exporting its products in small quantities to nations in the Middle East, as well as markets in the US. Spurred on by the COVID-19 crisis, the company has also increased its focus on online solutions for its customers. “The dynamism of markets has shifted a bit towards online now, and a lot of online sales are happening,” Jasbir confirms.

“So we have onboarded online customers and we are moving in tandem with industry trends for offering solutions for room air conditioners to our customers online.” One thing that sets Amber Enterprises apart from the competition is its focus on R&D, which allows it to offer designs tailored to changing market needs. “We offer very unique solutions to our customers by giving them energy-efficient products,” Jasbir points out.

Growth for everyone

Amber Enterprises’ goals revolve around viewing itself as part of a wider ecosystem of customers and suppliers, and using that network to build on its growth of the past two decades in order to become the market leader. Its vision is to be the first choice for customers, to add value to customer businesses, and to run its operations with discipline and strong management principles. Its mission is to be the number one manufacturer of components and OEM products, while offering excellent services to customers and creating growth for every entity associated with its organisation. That is all underpinned by a philosophy of smart working, innovation and ensuring all stakeholders are happy.

“Then our hybrid strategy of offering components as well as finished goods is very unique. We are a one-stop integrated and comprehensive solution provider in our industry.” The company’s presence in numerous locations, allowing it to be strategically close to customers, is also a major strength. “Our strength is our diversified product basket and a presence in different geographies, with 15 plants in India” he adds.

Long way to go

Amber Enterprise’s competitive advantage is not based on any single factor, but rather on its integrated approach to offering comprehensive solutions with a large reach, powered by its commitment to innovation. All of this is made possible by durable relationships with suppliers. “We have a practice of treating vendors as our business partners,” Jasbir says.

We continue to have our old suppliers with us, and we believe that knowledge sharing is very important because the ultimate aim for our suppliers, and for us as a supplier, is to grow. We should make sure there is growth for everybody, including our customers.

“Bringing that concept to life means growth for everybody, and we have constantly strengthened our relationships with our suppliers over the past 20 years.” Many of the company’s suppliers have been with Amber Enterprises since the company’s early days, providing key materials and parts, including copper tubes, aluminium foils, different types of steel, resin solutions and compressors.

“We have been working with the compressor manufacturers for many years, and those relationships have benefited us as compressors become more energy-efficient,” Jasbir reveals. To make these relationships as mutually beneficial as possible, Amber Enterprises is committed to the sharing of knowledge as well as carefully guiding suppliers that may be newer or less experienced.

“We continue to have our old suppliers with us, and we believe that knowledge sharing is very important because the ultimate aim for our suppliers, and for us as a supplier, is to grow. We should make sure there is growth for everybody, including our customers,” Jasbir explains.

“With that in mind, we continue to hand-hold many of our suppliers for improvement of processes, for quality improvement and so on.” Much of this hand-holding serves to bring partners up to speed with the company’s approach to quality, cost, delivery, innovation and safety, or QCDIS as it is referred to, which is aimed at ensuring operational excellence while cementing Amber Enterprises’ strong market position.

“When you are a very QCDIS-focused company, and you’re a very transparent organisation, you by default become a first choice for the customer,” Jasbir says. “That is Amber’s vision – to be the first choice of any customer. Theoretically, it sounds very nice to say that you are the first choice, but you cannot be the first choice if you are not first in every parameter.

“You must be first in quality, cost, delivery, innovation and safety. That is what builds long-term relationships with your customers, and that is how Amber has grown with complete transparency. Then we have added R&D capabilities, where we have started giving them ODM solutions, which has helped us to maintain our long-term relationships with our customers.”

Proud History

Amber Enterprises’ first factory in Rajpura, Punjab, started its operations in 1994. Today, the company has grown to have a major presence in the room air-conditioning market, with 15 facilities across India. Its facilities have opened in accordance with a strategy of becoming backwardly integrated, and are placed strategically to help the company better meet customer needs. Here is a time line of the company’s growth:

1990 Amber Enterprises India is incorporated as a private limited company.

1994 Its first factory opens in Rajpura to produce sheet metal components for tractors, automobiles and the telecommunications sector.

2001 The company begins manufacturing room air conditioners to meet growing demand from consumers seeking more comfortable living.

2004 The Dehradun Unit factory is established to manufacture RACs and sheet metal components for captive usage.

2007 Heat exchangers for captive usage and supply become part of the company’s offerings.

2008 The company starts the Noida Ecotech Unit, which adds plastic extrusion and vacuum forming to its product portfolio.

2009 Another unit is added at the Dehradun factory to build up the company’s capacity for original design manufacturing.

2010 The company establishes three more units to boost its sheet metal component offerings. A sixth unit opens at Dehradun to increase ODM capacity even further.

2012 Amber Enterprises expands its geographical presence and adds a new customer base by establishing a facility in the city of Jhajjar, in the northern state of Haryana.

2012 Amber Enterprises makes its first acquisition by buying PICL, a manufacturer of electrical motors.

2013–16 The company begins a major shift towards expanding its product range in the ODM finished goods category.

2018 The company is listed on the National Stock Exchange of India and the BSE with a successful initial public offering.

2021 With a small number of exports to the Middle East and the US, the company begins its journey towards global expansion.

Amber takes a focused approach to its partnerships which enables it to identify those that are the most strategic using an ‘ABC’ analysis. The company has 17 or 18 companies in the A category of suppliers, which it considers absolutely key, and as a result, has invested large amounts of time and energy into ensuring they grow along with it.

“They have been working with us for a long time, and they have added a lot of value to our complete ecosystem. These are great partnerships,” Jasbir asserts. While the number of people enjoying the comforts of home air conditioning in India has grown many times in the past two decades, thanks in large part to Amber Enterprises’ efforts, there is still far more potential to be tapped in this market.

“I see the room air conditioner as one of the products with the lowest penetration,” Jasbir says. “There is still just eight per cent penetration here. There’s a long way to go and we will remain a very focused player in the sector.”

Proudly supported by: