Transforming an entire industry is a challenge that most would shy away from. But for Kent Teh, Director of Manufacturing for Esquel Garment Manufacturing (Vietnam), it’s a challenge his company not only wants to take on but feels it has a responsibility to as well.

Hong Kong-based Esquel Group is one of the largest cotton shirt makers and exporters in the world, producing more than 110 million garments annually, with a workforce of about 55,000 and an annual revenue of more than US$1.3 billion. Esquel is the name quietly sitting behind global brand heavyweights Nike, Patagonia, Calvin Klein, Lacoste, Ralph Lauren, Tommy Hilfiger, Muji and Hugo Boss.

With state-of-the-art production facilities in China, Malaysia, Mauritius, Sri Lanka and Vietnam, and strategically located merchandising offices worldwide, Esquel also distributes through its own retail brands, PYE and Determinant.

The Vietnam division of the company commenced operation in 2001, taking advantage of an emerging economy with good infrastructure, connectivity and a talent pool of young, skilled workers. Kent was appointed Director of Manufacturing in 2008.

The performance of Esquel’s Vietnam subsidiary has been impressive, with revenue growth increasing from US$27 million in 2008 to nearly US$220 million in 2018. “Vietnam is the company’s biggest operation outside China now,” Kent says. “It used to be very traditional, but we saw the potential to transform the business.

“We focus on how we can make a difference in the industry rather than just follow trends. Many manufacturing companies migrate operations to reduce operating and material costs. Africa and Cambodia appear to be where the industry is moving now,” Kent adds. “But every time you move, you lose the incentive to innovate and invest. We made a point of saying, ‘Let’s not move,’ and instead introduced technologies to help us achieve better efficiencies and productivity.

“We focus on how we can make a difference in the industry rather than just follow trends.”

“We can be competitive and profitable as long as we continue to invest in people, technology and processes. We focus on internal organic growth rather than just adding more factories or growing the workforce. We want to use less for more.”

Fast fashion relies heavily on low manufacturing costs and endless churning to meet the demand for 80 billion new garments each year. This has created a global network of low-paid workers largely from developing countries and mostly female.

Fashion’s dirty secret is also the demand on natural resources and volumes of hazardous waste produced during manufacturing. As a result, the textile and garment manufacturing industry has a poor reputation.

“We want to make a difference in how people perceive the industry,” Kent says. “We want to build an industry that’s responsible to our community, environment and employees.

“Esquel is passionate about sustainability and we hope our efforts can make an impact on climate change issues. People will always wear shirts so this industry will continue forever. It’s our responsibility to manufacture products in a way that doesn’t destroy our natural environment. We can do this by limiting energy and water consumption and chemical use.”

“People will always wear shirts so this industry will continue forever.”

As a result, Esquel has reduced energy consumption per unit of production by 49% and water use by almost 67% over the past 12 years.

“Esquel is different from other manufacturers. Our sustainability initiatives come from ourselves. It’s not something we’re being pushed to do. We’re not just meeting a compliance requirement; we genuinely want to do more than the minimum. This comes from our board, our chairman and at all levels in the organisation. We know it’s the right thing to do and we have to do it.

“I think customers are becoming more aware of the importance of climate change and the environmental impact of their choices. In the future, consumers will care more about how the products they buy are manufactured.

“They’ll want to know their garments are produced in an ethical and sustainable way. The Ecologicals is an Esquel product line that pushes the boundaries of sustainability in fashion and raises awareness of ‘green’ clothing and production,” he comments.

“We want to change the industry,” Kent says. “But more manufacturers need to do the same so the industry will start to transform and customer perceptions change. One company alone is not enough.”

Building a vertically integrated supply chain has been key to Esquel’s success as a sustainable business. Internal vertical integration allows Esquel to control processes, reduce costs, improve efficiencies and, most importantly, build sustainability into each process in the supply chain.

“We believe it’s difficult to say that you’re sustainable if you don’t have transparency of your supply chains,” Kent says. “A lot of companies claim their products are sustainable, but if they can’t control how they are made and all the processes in the supply chain, then this may not be true.”

In an industry where competitors rely on outsourcing and specialisation, Esquel does everything itself, including cotton farming, spinning, weaving, dyeing, knitting and distribution while controlling energy and water consumption and waste management procedures. “We’re not just making shirts – we’re also making a difference,” Kent says.

To guide its approach to its people, Esquel proudly employs a ‘5E-Culture’ strategy, which encompasses ethics, environment, excellence, education and exploration. “We believe in developing leaders from within the company,” Kent says. “The introduction of innovative technologies such as robotics give our people the opportunity to upskill.

“We want to create a learning environment, remove repetitive roles and make jobs more meaningful. We’re changing the traditional model. We believe future success is based on how fast we can learn.”

Kent sees himself as a mentor for the team. “We focus a lot on developing our people,” he says. “My job is to empower them and give them the platform to perform. Everyone has a role to play in shaping the work culture of the company. We all should have the courage to do that.

“I want the next generation of managers to be better than me,” Kent laughs. “The future competition is going to be greater so they need to be.”

Caring for employees is key to the company and underlies its goal to be best in class for working conditions. “We’re trying to achieve better work–life balance for our staff. Technology helps us to be more efficient and reduces overtime,” Kent explains.

“We want to make a difference in the industry by moving towards zero-overtime targets. Nobody believes that the garment industry could have zero overtime, but we believe it’s possible with better planning, strong management and smarter supply chains.”

Strong supplier relationships are essential for the continued success of the vertically integrated supply chain that Esquel operates. “Suppliers should be treated as partners. We treat our suppliers how we would like our customers to treat us,” Kent says.

“If they can’t make a profit, then they can’t serve me. Instead, I’ll receive inferior service or inferior quality products. We just can’t focus on our price. We want to work with suppliers who have the same values as us.”

Esquel has seized the opportunity to be the difference in the textile manufacturing industry. Now, as a proactive agent of change, the company is changing the industry as businesses and consumers realise it doesn’t have to be this way; sustainable products and practices are showing them this.

“We want to remove the negative perceptions about the industry,” Kent adds. By transforming the things that created these perceptions in the first place, Esquel is offering hope that this change will eventually come.

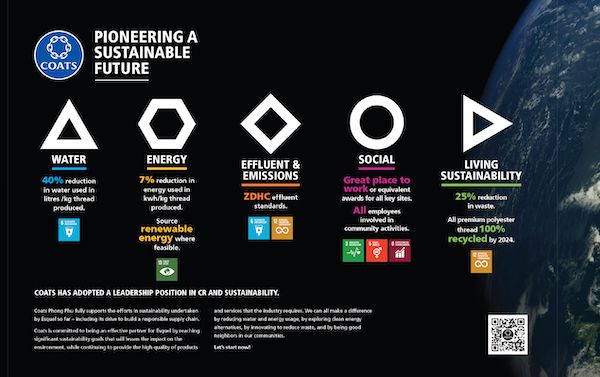

Proudly supported by: