Ensuring quality in a US$410 billion-dollar industry is no small task. But when the industry in question is Germany’s automotive industry, with its global renown for excellence, the stakes are even higher.

Joachim Himmelsbach, Managing Director and Chief Technical Officer of grinding machine manufacturer Junker Group, understands that a reputation for quality is not something that appears overnight. Instead, it is crafted over years, even decades, of uncompromising dedication to the needs of your customers.

“The focus is always on high precision,” Himmelsbach tells The CEO Magazine from his office in Nordrach, Germany.

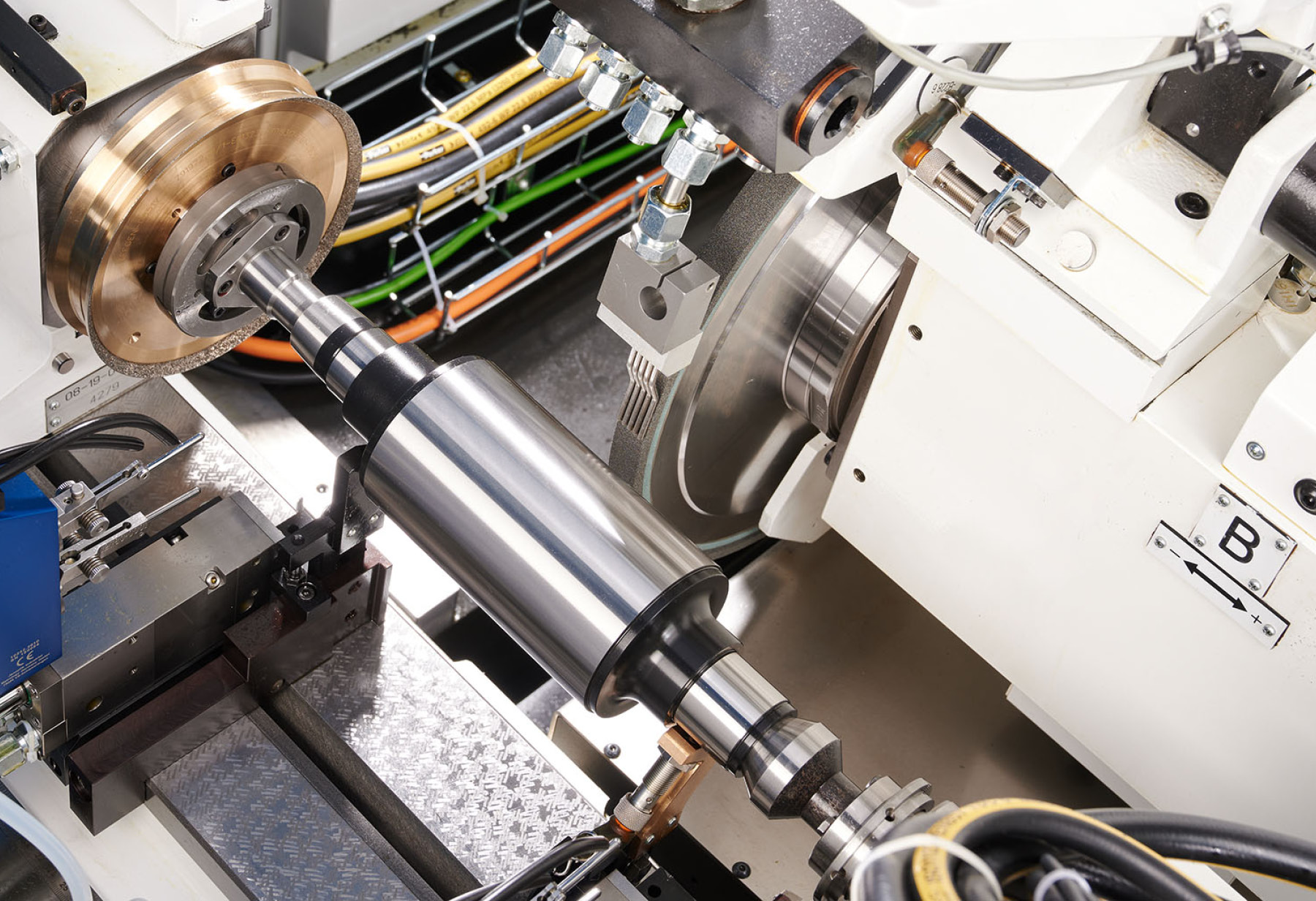

A global leader in the production of grinding machines, Erwin Junker started life in Germany in 1962 in an abandoned grain mill. The manufacturer soon expanded abroad and has since begun producing air filtration as well.

Today, under the stewardship of Himmelsbach, Junker Group is the global leader in cubic boron nitride grinding, with its machines being used widely in many sectors.

“I know nearly every employee in the company.”

Yet sands are shifting in the automotive world, and Himmelsbach is looking to drive Junker Group to new horizons. “We are well known in the automobile industry. Now we want to export our success into different market areas.”

Climbing the Ranks

Himmelsbach’s plan to take Junker Group into the future is informed by his rich history with the company. His 31-year career at Junker Group has seen him rise from an apprentice designer in the technical department all the way to Managing Director, giving him a unique understanding of all facets of the business.

“I learned from the bottom, everything from the smallest details of our machines up to the complete system,” he says.

He has experience with every department and understands the value each one of his 1,200 workers provide to the final product.

“I know nearly every employee in the company,” Himmelsbach reveals. “It’s very helpful when you have long-term relationships, they support you every day at work.”

These relationships are a key part in driving Junker Group’s unmatched ability to problem-solve.

“Our customers are not just buying a grinding machine; they are buying a complete solution,” Himmelsbach says. “We are responsible for quality across the whole supply chain.

“We are always looking for ways to save costs for our customers, so Junker remains two steps ahead of our competitors,” he says.

Recognizing the issue of labor shortages across Europe, Junker is offering its own expertise to ensure its customers are operating their grinding machines at their full potential.

“We are always looking for ways to save costs for our customers, so Junker remains two steps ahead of our competitors.”

Junker Group also has an award-winning record in sustainability. Their machines were awarded a silver medal by sustainability assessment platform EcoVardis, recognizing their environmental efficiency. Yet, far from being self-satisfied, Himmelsbach sees this as a logical element of their culture.

“To be honest we don’t make a lot of noise about it. We take a lot of care about our consumption of electricity, coolant flow and water. For us, it’s natural to do this in relation to our customers, to save energy and reduce their costs.”

Precision Partner

Along with the company’s commitment to sustainability, Himmelsbach’s wealth of experience has left him in good stead to lead Junker Group to further success. He sees the chance for expansion into new markets.

“We want to be more popular in markets beyond the automobile industry, such as aviation,” he says. “We also want to enlarge our business in the United States, Mexico and Brazil and to build on our current success in India.”

He is aware of the challenges to overcome, such as adapting to the shifting approach Junker Group’s key customers are taking to purchasing.

“Car manufacturers are no longer directly purchasing our grinding machines. Instead, they are outsourcing to other companies in the supply chain,” Himmelsbach says.

“Therefore, we have to communicate to them who we are, what products and services we provide and the difference that purchasing a Junker machine can make.”

“Some customers are only looking for the price, but the cheapest price will not give you the best solution.”

Like any business, effective supplier relationships are of the utmost importance for Junker Group.

“We have good suppliers with good long-term partnerships, where we can trust them on price and delivery time,” Himmelsbach says.

One such supplier is SwissChuck, which has developed a long-term strategic partnership with Junker Group. It provides Junker Group with high-precision clamping tools tailor-made for their grinding machines.

With the help of trusted suppliers, the company can continue to deliver on its motto ‘Partner for Precision’.

“Some customers are only looking for the price, but the cheapest price will not give you the best solution. The long-term benefits customers get from a Junker solution will help them get the best out of their business.”