The rise of zinc through the busy and lucrative hierarchy of Indian mining could best be described as meteoric. In 2006, India’s contribution to the final tally of global zinc production barely cracked five percent. By 2021, the country had become the world’s fourth largest producer of the element, responsible for 776,000 of the 13 million metric tons mined that year.

The story of how this dramatic escalation came about is, in large part, the story of Hindustan Zinc.

The tale begins centuries ago in British India, where mining was one of the pillars of society. The British Raj owed its very existence to mining, having been formed as a result of the East India Company’s relentless pursuit of natural resources beyond British borders.

Early trade between the two nations was an evolution of the ancient Silk Road system, and as such involved spices and textiles. It wasn’t until the British government began to take increased control of Indian territory that vast swathes of resources were discovered. Before long, those resources – salt and coal in particular – were essentially being looted, mined and exported to expand the wealth of the British Empire, with Indians themselves doing the lion’s share of the mining.

It was during this time that the seeds of India’s future as an industrial powerhouse were sown. Indians working in the fledgling mining industry were keenly aware of their country’s hidden riches and several founded their own mining companies to take advantage.

Indians working in the fledgling mining industry were keenly aware of their country’s hidden riches and several founded their own mining companies to take advantage.

Starting small

One such company was the Metal Corporation of India, founded in 1944. Just three years later, India won its independence from the United Kingdom. No longer bound by ties to a foreign power, companies such as the Metal Corporation of India began to flourish.

The newly established Indian government was soon to capitalize on the mining situation, incorporating successful companies as part of its own Public Sector Undertaking program. In 1966, the Metal Corporation of India’s zinc operations were acquired in such a way, becoming Hindustan Zinc.

The company remained under government control until 2002, when it was sold off as a loss-maker. An underperformer it may have been, but once in private ownership Hindustan Zinc began to find its feet.

At the time, together with Binani Industries, Hindustan Zinc was one of only two players in India’s zinc industry. Today, Hindustan Zinc’s parent company, Vedanta Resources, owns the five largest zinc mines in India, earning its place at the top of the country’s zinc ladder.

Big deal

In fact, Hindustan Zinc’s prodigious output is almost single-handedly responsible for taking India to the heights it currently enjoys in the world market. The company holds approximately 80 percent market share of India’s primary zinc industry. It remains the country’s only integrated producer of zinc, lead and silver, and boasts a capacity of 1.1 million metric tons of ore mined per annum.

Half of that comes from just one of Hindustan’s mines, Rampura Agucha, which is the world’s largest underground zinc mining operation.

This year, for the first time in a decade, we crossed the one million ton mark in terms of metal in concentrate production, which makes us so proud.

In addition to its own lineup of smelters, Hindustan Zinc’s access to some of India’s largest and oldest smelting complexes is another factor in its favor. The company’s capacities for metal production have increased five-fold since 2002.

Impressive as this is, Hindustan Zinc has no intention of slowing down anytime soon. Expansion plans are already underway and despite the hurdle of the COVID-19 pandemic, CEO Arun Misra says business is booming.

“Production numbers and profits have improved year on year,” he notes. “This year, for the first time in a decade, we crossed the one million [metric] ton mark in terms of metal in concentrate production, which makes us so proud. Having said that, and even though the 2022 financial year was one of our best years ever, we still have miles to go.”

As does Misra who, although being in the industry for over 31 years, is still relatively new to the CEO role. “I took over just as COVID-19 hit,” he says. “It was a very daunting task. COVID-19 was an absolute unknown. We saw lockdowns and factory stoppages, health issues among 25,000 employees. As CEO, you have a moral responsibility to look after each and every employee and their family members.

“At the same time, you have to keep the wheels of the business and the economy going. Operations must continue, we must produce value results. So it was quite a balancing act, but we handled it quite well.”

Chasing modernity

One of zinc’s many uses is as an essential part of the manufacture of galvanized steel. A Tata Steel veteran, Misra says Hindustan Zinc’s reputation in the industry preceded it. “We knew it as a company with a high level of expertise at open cast mining of a very high quality,” he reveals. “Then in the last few years before I joined, it had migrated to underground, and it began very slowly putting itself on the map as the most modern underground mining company.”

By the time Misra arrived in November 2019, other industries had caught up to, and in some cases surpassed, Hindustan Zinc’s modernity. “Coming from Tata Steel as I did, what struck me was that the steel companies had become the most modern,” he acknowledges. “But all steel plant productions are very predictable. Day on day, month on month – numbers weren’t a challenge.”

In contrast, Hindustan Zinc’s brave new world of underground mining represented exactly the sort of challenge Misra was seeking. “Local skills weren’t readily available, so business partners were mostly from foreign countries,” he adds. “I set myself a goal: to achieve the level of day-on-day predictability I’d become accustomed to in steel.”

Even though 2021 was one of our best years ever, we still have miles to go.

When he ascended to the CEO position in August 2020, Misra began with a tall order: an evening call among the company’s various sections every day, without fail. “We did that religiously from the moment I took over,” he says.

“And what it did was bring the whole company together. Anybody in any part of the organization, whatever their role, would know how much metal we’d sold that day, how much money we’d earned, and crucially, what was stopping us from doing more.”

The nightly calls also became a community forum of sorts, with workers able to float ideas and vent about problems. “It was a platform for coordination issues, working needs, communication breakdowns,” Misra explains. “Whatever issues crop up each day, we’re resolving then and there.”

Healthy resources

And so Hindustan Zinc began to gain momentum. Monthly results kept improving, particularly compared to years gone by. The company’s social media presence improved and before long was a vibrant point of connection between Hindustan Zinc and the public. “We’ve built up a lot of goodwill in the minds of the people,” Misra remarks. “That’s reflected in our sustainability and indulgence index ratings, which have both moved up.”

Sure enough, in 2021 Hindustan Zinc retained its top five ranking on the Dow Jones Sustainability Index, in addition to its number one spot in the mining and metals sector in the Asia–Pacific region. “Our results speak for themselves, and they say that we’re moving in the right direction,” Misra says.

Once momentum is built, slowing down becomes difficult, but fortunately, that’s not part of the plan. Hindustan Zinc has made a commitment to its shareholders that it will hit 1.5 million metric tons of metal produced in the next three years. To do so, the company needs more mines.

“Relying on old mines means your resource mix becomes poorer over the years,” Misra explains. “New mines help us remain cost competitive.”

Mine All Mine

The crown jewel of Hindustan Zinc’s mining network is Rampura Agucha, the world’s largest underground zinc mining operation. In the 2022 financial year alone, the mine produced 4.51 million metric tons of ore with a zinc-lead reserve grade of 12.8 percent on average. Commissioned in 1991, Rampura Agucha is outfitted with Hindustan Zinc’s state of the art technology, a development with an ultimate ore production goal of 6.15 million metric tons per annum.

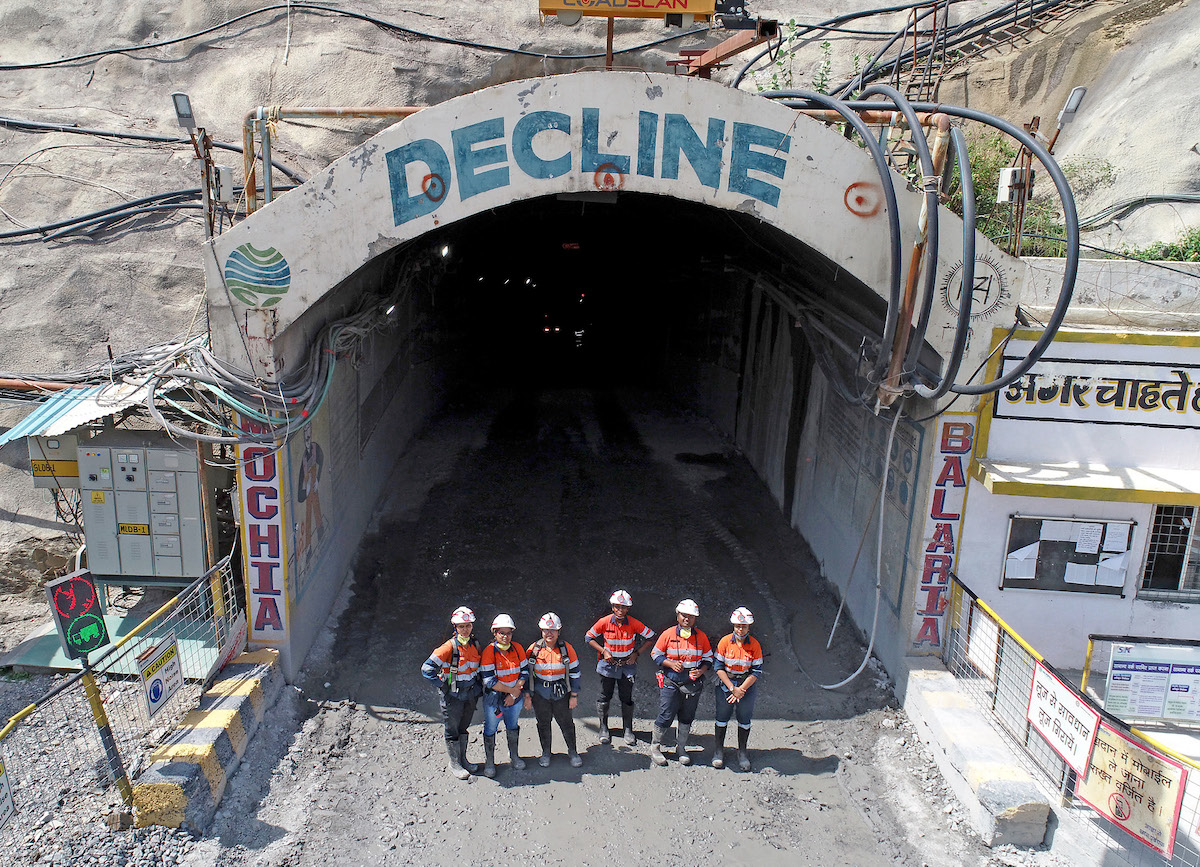

Hindustan Zinc’s oldest mines are the Zawar group of mines, which also the world’s oldest zinc mining site and produced 4.41 million metric tons in the 2022 financial year.

The Zawar site is the oldest with an array of four mines located just south of Hindustan Zinc’s home base of Udaipur. The site, made up of the Mochia, Balaria, Zawar Mala and Baroi mines, is powered by one of Hindustan Zinc’s coal-based captive thermal power plants nearby. The 2020 financial year saw the site produce three million metric tons of ore from a reserve of 14.2 million metric tons.

Sindesar Khurd, a world-class silver-rich mine, with state of the art infrastructure facilities and best-in-class mechanisation, is also a part of the Hindustan Zinc network. Its current capacity of six million metric tons keeps the underground mine workers busy; in the 2022 financial year, ore production reached 5.23 million metric tons.

Meanwhile, exploration continues at Hindustan Zinc’s Kayad mine, which opened in 2013. While it managed a total output of 900,000 metric tons in the 2022 financial year, it’s hoped Kayad’s mineral resource can be further increased over time.

Zero tolerance

The biggest challenge facing Hindustan Zinc is one faced by all companies, regardless of their productivity. Climate change has forced the resources sector to confront a net zero future. Once thought of as a pipe dream of environmentalists, net zero has become a reality for industry titans.

Not to be left behind, Hindustan Zinc has led the way by going beyond a simple 2050 net zero commitment. “The entire world has committed to that,” Misra says. “But we’ve also picked up goals of our own for 2025.”

True to form, Misra has set a high bar, and so far Hindustan Zinc appears to be set to clear it. “I have a plan to get rid of all thermal power plants in 10 years. I want to convert all our underground fossil fuel equipment to battery operated, including heavy vehicles, in five years. I want the 600 megawatts of power we need for operations to come from renewable sources,” he states.

That’s already happening. Hindustan Zinc has just signed a power purchase agreement for renewables to replace 200 megawatts of thermal energy by 2024. “Net zero is the biggest challenge we have to face and we have to live up to it,” Misra declares. “We are already in action.”

Sustainability is no longer an option; environmental awareness is what separates businesses.

And it shows. At the GreenCo Summit 2022, Hindustan Zinc enjoyed a triple sweep of awards. Its Dariba Smelting Complex achieved the coveted GreenCo Gold Rating, as did its Chanderiya Lead-Zinc Smelter. At the same event, Hindustan Zinc’s Debari Zinc Smelter achieved the silver rating.

At the time, Misra chalked up the wins to Hindustan Zinc’s unwavering prioritization of sustainability and environmental compliances. “Urgency during COVID-19 has made businesses aware of their responsibility in developing sustainably,” he told the conference. “Sustainability is no longer an option; environmental awareness is what separates businesses.”

Next level

An expanding company means an expanding workforce, which isn’t always easy in an industry as specialized as zinc production. “If you grow to these volumes, so must the skill of the people working for you,” Misra explains. “In India, such a skill level in underground metal operation of this scale, 20–30 million [metric] tons or more, is not there at all.”

The solution was deceptively simple to arrange. Hindustan Zinc is opening an academy to upskill its workers and educate the next generation to a world-class level.

There’s also the matter of an expanding product range. With a background in mineral engineering, Misra knows that there’s more to be found beneath the ground. “We know there is a demand for many more alloys or other forms of zinc,” he says. “To meet that would require very high reliability in terms of product quality, delivery and commitment to the customer.”

To meet that goal, Hindustan Zinc has established a subsidiary, Hindustan Zinc Alloys, which will specialize in the production of alloys through melting tests in a custom facility. “A substantial portion of our products should be aligned where the margins are protected,” Misra declares. “And we’d be able to build the commodity cycles as much as possible.”

The first stage of this footprint expansion involves the establishment of a new plant with a capacity of around 30,000 metric tons per annum, which would be responsible for zinc alloy product manufacturing. The plant, which will enable Hindustan Zinc to deliver international quality products on the domestic front, is planned for Dariba, Rajasthan.

The look of success

With a clear plan to reach the next level of success, Misra has lived up to his promise as CEO. His record of excellence and position as one of the industry’s top thought leaders has also been recognized beyond Hindustan Zinc’s walls. He was named CEO of the Year at the World Leadership Congress’s Business Leader of the Year Awards in 2021. At the same event, Hindustan Zinc won ‘Most Innovative Company of the Year’ – no small feat during a once-in-a-century global pandemic.

Hindustan Zinc won ‘Most Innovative Company of the Year’ – no small feat during a once-in-a-century global pandemic.

In early 2022, Misra was named Chair of the International Zinc Association – a first for an Indian (this in addition to his role as Vice President of the Indian Institute of Mineral Engineers). Through this position, he has helped promote the importance of zinc around the world, particularly as innovations abound, requiring its unique qualities. An appropriate leader, then, for such unprecedented times.

For Misra, however, success is best determined by performance. “When you deliver to your stakeholders what you’ve committed to, that’s success,” he states. “If you can keep the costs of innovation at a constant while expanding the company, that’s success.”

New tricks

The ‘Most Innovative Company of the Year’ certainly didn’t earn that title by doing what’s always been done. Hindustan Zinc’s track record shows a company prepared to take risks at the riskiest times, and uncomfortable to coast during the good times.

In the midst of the COVID-19 pandemic, it launched an Indian first: Evolve, an e-platform for purchasing non-ferrous metals. The aim was to extend the company’s relationship with purchasers of zinc, lead and silver through a wide network that’s always growing. Even the venture’s name is indicative of the desire to evolve the way metals are purchased in India.

The COVID-19 pandemic also brought about a number of health measures Hindustan Zinc implemented posthaste for staff and their families. “We conducted vaccinations for all our employees and their families completely free of cost,” Misra reveals. “When the Delta wave hit, people were dying because of a lack of oxygen, so we supplied oxygen from our smelter to hospitals nearby.”

Not satisfied with this, Hindustan Zinc also established an underground ambulance and first aid station for its workers, a first for India.

Also during 2021, after a change in national regulations of underground mining, the company demonstrated its commitment to diversity by appointing the country’s first female underground mine managers.

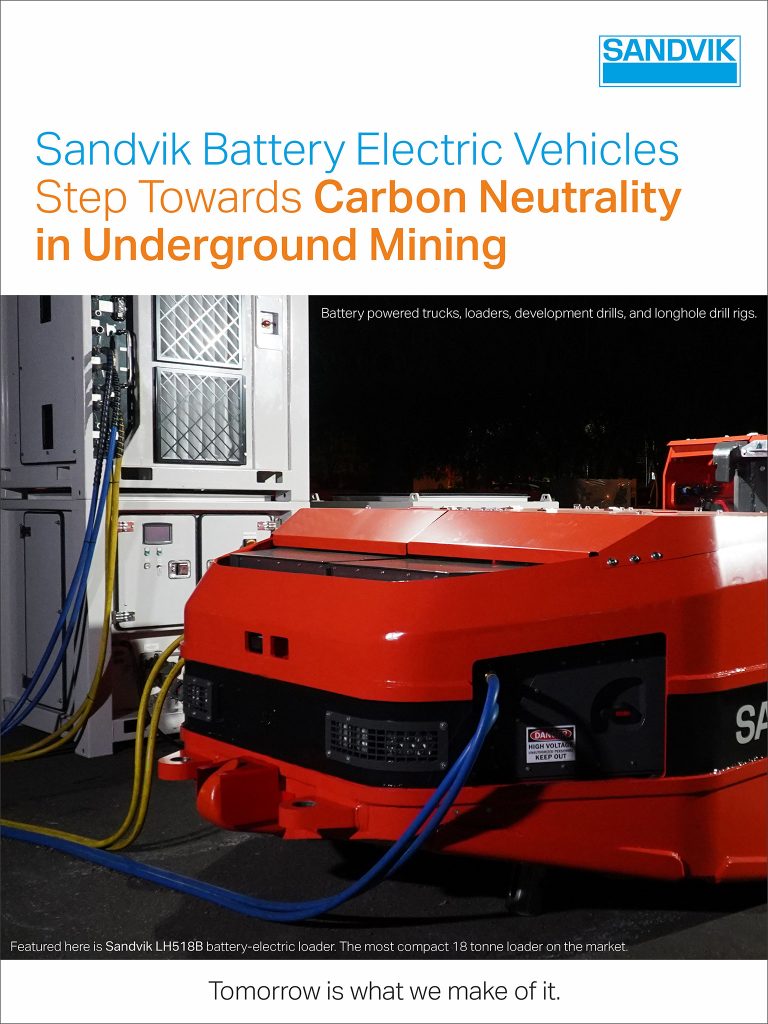

On the sustainability front, 2021 saw Hindustan Zinc and Normet & Sandvik sign a memorandum of understanding for the introduction of battery electric vehicles in underground mining operations. The deal made Hindustan Zinc the first mining company in India to put electric vehicles to work in underground mines.

Net zero is the biggest challenge we have to face and we have to live up to it.

Above ground, Hindustan Zinc launched the Zinc Eco Buddies platform that allows people to make virtual green pledges. For every signatory, the company plants a tree in their name. It’s hoped the drive will improve biodiversity and land restoration efforts impacted by mining.

With so many progressive and pioneering moves under its belt, it’s no wonder Hindustan Zinc was certified as one of India’s Great Places to Work by the Great Place to Work Institute that same year.

Partners in mine

But as much as Hindustan Zinc has achieved, particularly under Misra’s watch, the old adage still holds true: you cannot do it alone. “Our business operations are 99 percent outsourced,” he says. “We’ve had to depend only on our business partners for success, and for the last two years we’ve been squarely focused on ensuring those partners have the right equity in place.”

This involves a carefully considered recruitment process for any new partners. “We extend the Hindustan Zinc brand to them and help them recruit the right people to manage their operations,” Misra says. “We also work with them to implement similar systems of safety, asset optimization and quality management in their own operations.”

By enhancing the operations of business partners and easing them into certain tasks, Hindustan Zinc is then able to take a back seat on those activities and concentrate on other matters. “We end up depending completely on partners to deliver,” Misra explains. “We also make sure to offer 10 or 20 year contracts rather than more standard three or four year terms.”

The result is a business partner that’s much more confident in making decisions and investments – essentially an extension of Hindustan Zinc itself. “We need our business partners to be focused on the end result of the business, which is that metal is being sold,” Misra points out. “What’s the point of an ore mining contract if that ore doesn’t deliver metal? If the alignment is there between Hindustan Zinc and all its business partners, then there’s no disconnect in goals and everybody wins.”

Currently, Hindustan Zinc has many key partners that play critical roles in its mining operations, as well as several key commodity suppliers. “We have detailed discussions with them regularly and I make my expectations clear,” Misra says.

“While I’m pursuing my ESG goals, I can’t have key business partners who don’t share those goals. I want them to strive for net zero emissions; I want them to embrace electric vehicles; I want them to ensure no human rights are violated among workers in their employment.”

All that goes towards ensuring that Hindustan Zinc’s virtuous qualities are passed on to its business partners. In that way, he says, such qualities become a movement across the country. “Then you have neat and tidy operations everywhere.”

Talk of the town

The respect with which Hindustan Zinc treats its external partners doesn’t waver within the company’s own walls. Entrepreneurship is one of the company’s key values; staff are encouraged to pursue their own goals and offered opportunities and resources to develop and grow with the company.

Trust is another of those values. Just as Hindustan Zinc clearly and uncompromisingly sets out its expectations and desires to its partners, the company works to foster a culture of trust and respect among its employees and stakeholders. Company-wide open dialogue is the key to this particular door.

The organization only works on governance, delivery of both quality and volume, contract management and safety practices of its business partners.

There’s also active communication on social media, something Misra has placed greater importance on since his arrival. Where many industry players have stagnating social media accounts that offer little insight into the goings on behind the scenes, the official Hindustan Zinc Twitter offers regular posts and interaction, and as a result enjoys thousands of followers.

Steady supply

While it’s clear that Hindustan Zinc stands in a league of its own in a variety of ways, the company prides itself on several key differentiators. One aspect that provides a great deal of reassurance to customers of the company’s zinc, lead and silver is its continuity of supply. “We have enough mines, more than enough to produce a steady capacity for the next 25 years,” Misra states. “Customers know that a break in supply will simply never happen.”

There’s also Hindustan Zinc’s method of dealing with its business partners, which Misra believes is unique to the industry. “There are very few companies I’ve seen around the world that operate like this, where everything is handled by partners,” he says.

“The organization only works on governance, delivery of both quality and volume, contract management and safety practices of its business partners. In a way, Hindustan Zinc’s role is limited to getting the best out of its business partners rather than trying to do everything itself.”

Doing so has helped Hindustan Zinc scale up quickly, he believes. “If you’re not comfortable with your own ability to invest, you can distribute the risk among 20 different business partners who individually can invest or take on a part of the job.”

Hindustan Zinc’s location has also proved a key point of difference between the business and its competition. “Where we operate in Rajasthan we enjoy a huge amount of sunshine,” Misra adds. “It’s ideal for producing solar power, so for us to migrate to becoming a renewable energy-driven company is easy.”

Digital underground

That’s in keeping with Vedanta’s vision of the kind of innovative and forward thinking company he’s sure Hindustan Zinc is well on the way to becoming. In many ways, he says, it’s already there. “Our processing plants are now automated. Process controls have been implemented. It’s an entirely touch-free operation with a self-learning system that detects everything and sets plant parameters,” he declares.

“Over time, the system teaches itself to operate better and better, replace human dependency and eliminate variations caused by human intervention. There’s a huge amount of technological innovation going on.”

There’s a greater need for such innovation in the mining industry than many of its contemporaries. The way mining is done today would be absolutely foreign to miners of the British Raj, although the inherent problems would remain familiar. “Underground mining limits the visibility of your operating equipment,” Misra says.

That’s where technology comes in. Hindustan Zinc has rolled out complete digital connectivity across its underground mines and connected them to its collaboration center. “Through our online portal we’re able to monitor equipment positions, the operator’s status, even various instrument gauges,” he continues. “You can see wheel levels, hydronic pressure, air pressure, so many parameters that all flow to what we call the collaboration center. It’s a huge amount of data.”

The potential of Hindustan Zinc is huge. And as we work to unlock that potential, we will continue to grow and flourish further.

That data is then sifted through by Hindustan Zinc’s eagle-eyed data scientists, who tirelessly search for patterns. Should any arise, serious safety concerns come into play. “The model may reveal that certain equipment may be days away from failure,” Misra notes. “That feedback is sent to the operating team, which carries out the maintenance work accordingly.”

Safety and productivity have been greatly improved in the mines, but back at the Hindustan Zinc office, even the HR department is seeing the benefits of the company’s flair for innovation. “We use SAP to forecast accounting mishaps and our HR systems are fully digitalized,” Misra says. “There’s quite a lot of technological implementation throughout the company.”

Good fortunes

Whatever role privatization played in Hindustan Zinc’s success is about to expand, too. In September of 2022 the Indian government announced its intention to sell its remaining 29.5 percent stake, worth more than US$4.4 billion, in the company.

In a reversal of the original sale, which came about due to Hindustan Zinc’s flagging fortunes, such is the company’s renewed financial might that this sale would help the Department of Investment and Public Asset Management (DIPAM) meet more than 50 percent of its disinvestment target.

The figures achieved by Misra and his team have gone a long way towards making DIPAM’s stake a very attractive prospect to potential stakeholders. Currently Vedanta holds a 64.92 percent stake while 5.5 percent is publicly owned, but that may change in the future.

Beyond the underground mines, Hindustan Zinc has a network of captive power plants that provide energy to its mines and smelters. While these were established to help keep costs down, their viability has come into question given Hindustan Zinc’s swing to sustainability.

Hindustan Zinc’s coal-fired CPPs have since been joined by wind and solar farms. In fact, Hindustan Zinc has become one of India’s largest wind power producers, capable of generating 273.5 megawatts.

Likewise, solar power has been put to good use powering the majority of Hindustan Zinc’s Udaipur head office. In addition to Hindustan Zinc’s three captive solar plants at Rampura Agucha, Debari and Dariba, the company has installed solar roof top projects around its network of buildings.

Unlocking potential

One of the inevitabilities of mining is that it literally changes the face of the land in which it occurs. True to its innovative form, Hindustan Zinc has subverted this reality and instead has worked to transform the face of mining in India.

The Right Stuff: Why Zinc Matters

Zinc plays a unique role in modern society in that it’s an essential ingredient in a wide range of everyday products. From galvanized steel to skincare products, zinc is there. Its primary use is as a protective surface for construction metals, and helps prevent corrosion and rusting. Galvanization by zinc can significantly prolong the lifespan of certain metals; steel in particular.

Zinc is also a powerful friend to the human immune system, having the power to fight infections, improve memory and restore vitality to hair and nails. A small daily intake of zinc, particularly through meat, seafood and dairy products, is enough to keep the body happy.

It’s not uncommon to find zinc in building exteriors, either. Used as weatherproofing in wall cladding, roofing and gutters, zinc can stave off the worst wear and tear brought on by the elements.

Despite this enviable track record of achievement, the potential of zinc to galvanize the next generation of tech innovation remains high. Industry experts believe zinc will be a crucial aspect of the ongoing electric vehicle revolution. Zinc-ion batteries, while an older technology, appear extremely promising as the industry scrambles to find an alternative to li-ion batteries, the ingredients of which are much scarcer (and less environmentally friendly).

It remains to be seen which technology will carry electric vehicles to ubiquity, but there’s no doubt zinc will be there in some way, shape or form.

Under two years of Misra’s leadership, Hindustan Zinc has reached heights undreamed of at the time of the company’s inception. For anyone else this would be enough, but for Misra, the work never ends.

“The last two years have been a fabulous learning experience,” he declares. “It’s a very encouraging and motivating place to work, but we’re not finished. As I said, the potential of Hindustan Zinc is huge. And as we work to unlock that potential, we will continue to grow and flourish further.”

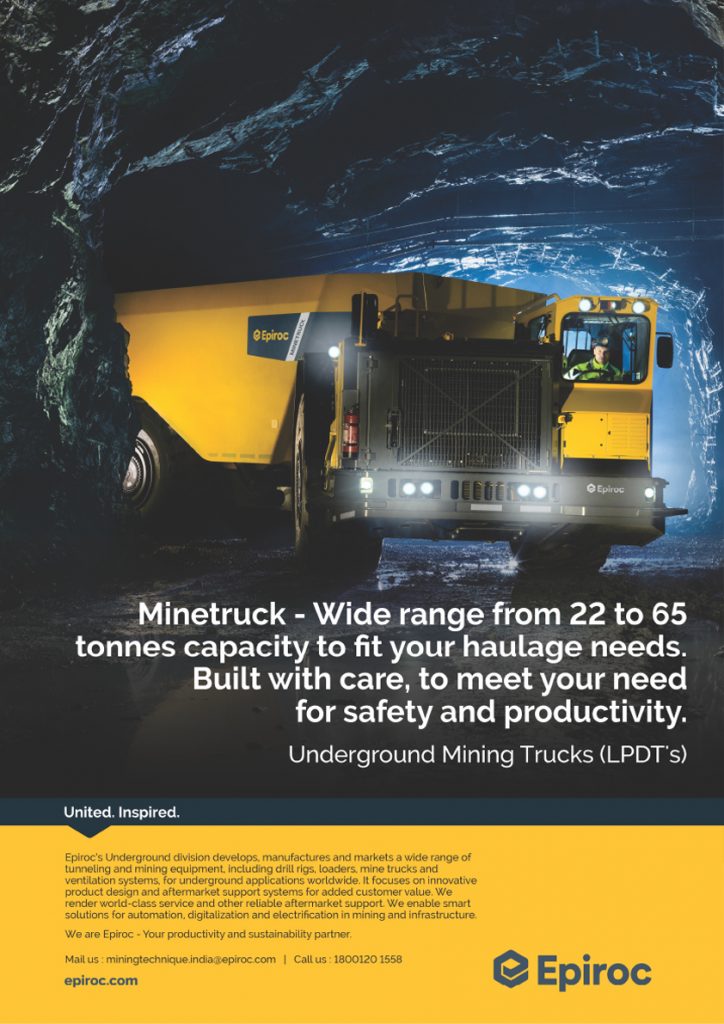

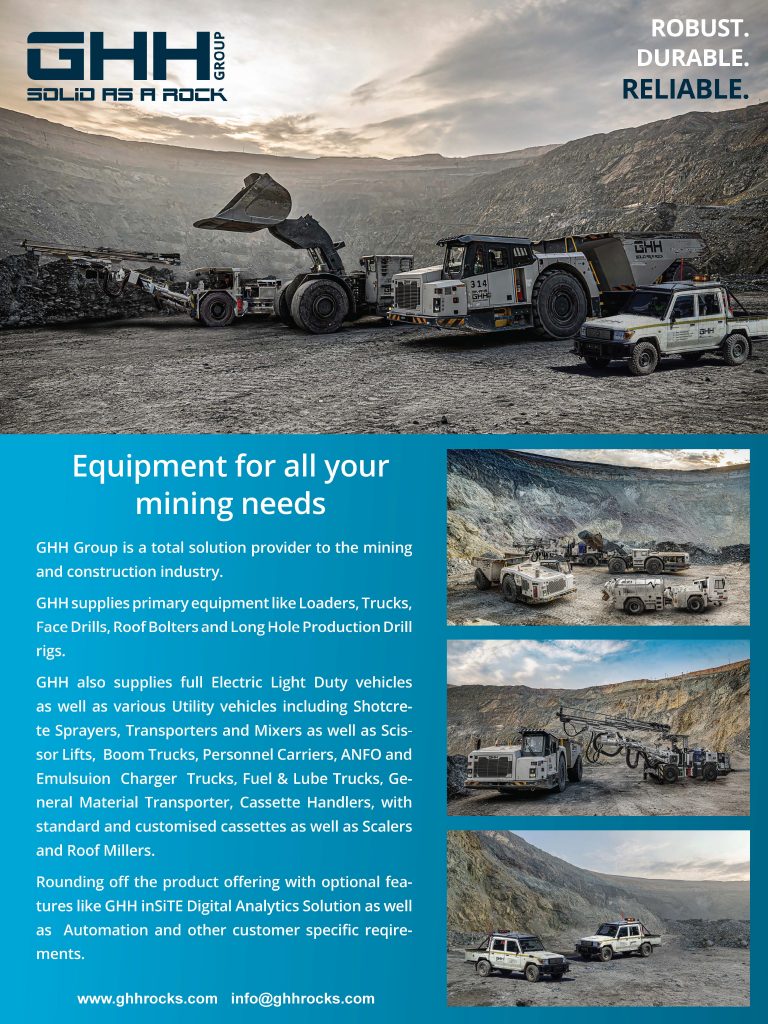

Proudly supported by: