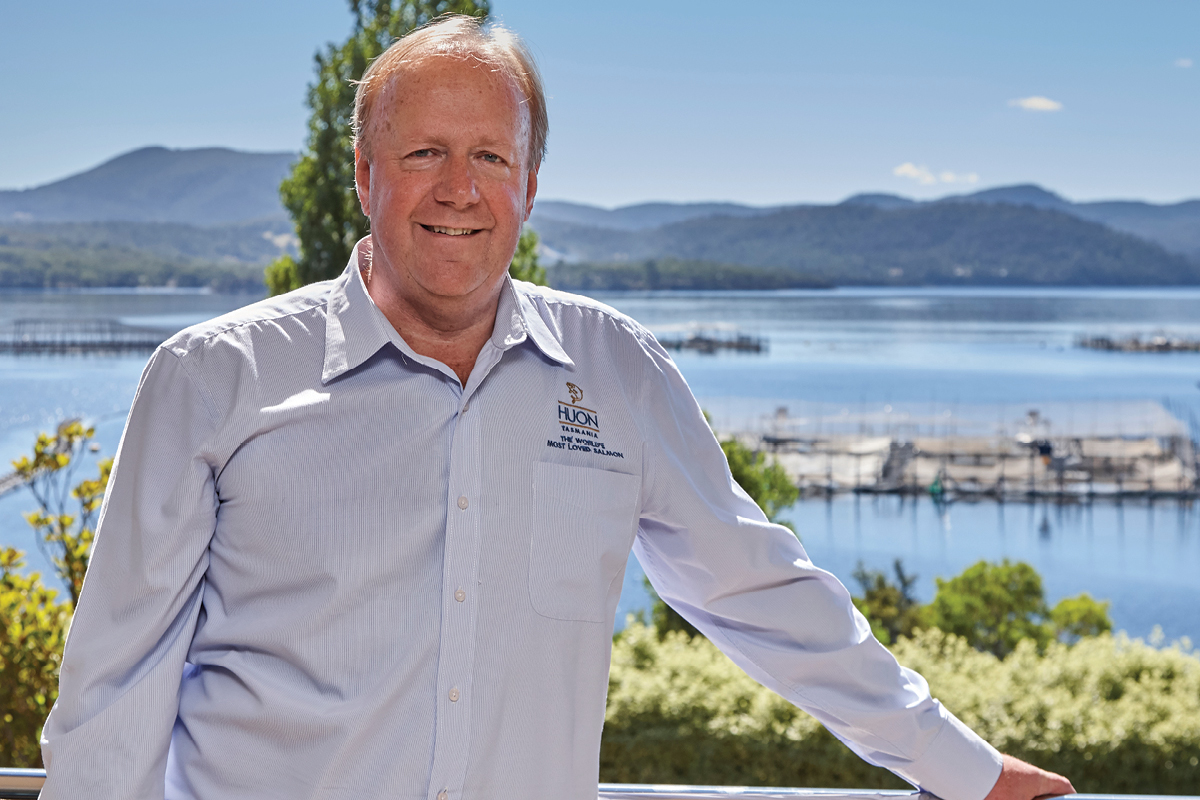

For Peter Bender, co-founder and CEO of Huon Aquaculture, an affinity for farming goes back to his earliest days. He grew up in a Tasmanian farming family and on weekends could often be found carting hay, working with stock and generally pitching in with labour around the farm.

After school, he worked on the property full-time, developing a particular affinity for working with the family’s Murray Grey cattle stud.

He had success working with cattle. “I used to enter steers in all the cattle shows,” Peter recalls. “We won many steer and carcase competitions and our herd become quite well known in Tasmanian and mainland breeding circles.”

He also spent time on the property of Mervyn Gadd, one of the leading cattle breeders in the country, further developing farming expertise, an attention to detail, and a respect for farm animals and their environment.

This early work might seem only tangentially related to his current role overseeing one of the Apple Isle’s leading salmon farms, but the tenets of good farming that he picked up from this early work remain paramount.

I was instilled with a great appreciation of breeding and growing quality stock

“I believe that this experience has helped me in my career as a salmon farmer as the principles are the same: look after the stock, feed them well, keep them in clean conditions, don’t overstock them and don’t stress them. If you stick to these basic animal husbandry principles you will do well whether you are growing cattle, sheep, pigs or salmon.”

While still working at the farm (and also running a butcher’s shop), Peter began a new chapter when he started an apricot orchard with wife Frances and schoolmate Steven Shield, the owner of a major apple orchard.

Recognising a gap in the Australian mainland market for stone fruit that came into season later, the trio successfully grew apricots for 14 years before things turned sour.

“In the end, we had to remove the trees as a spray we used on the orchard didn’t do what it said on the label and instead harmed the trees.”

In 1986, just two years after the apricot farm was established, Peter and Frances founded what would become his best-known venture, Huon Aquaculture in picturesque Hideaway Bay on the Huon River.

At that stage, salmon was a very minor part of the Australian seafood diet. While the salmon farming business was initially intended as a diversification of the family farming business, it soon overtook the apricot orchard in volume.

Still, growing fruit had been a formative experience. “While it was unfortunate to have to pull out the orchard, it was an important lesson early on. Ever since then, I don’t like using any chemicals in farming our salmon.”

The Huon method

The avoidance of chemicals is just one element of a philosophy that informs Huon’s philosophy on farming. “The essence of the Huon method is care,” Peter explains.

“Caring for our fish means that they are treated as well as possible right up to, and including, when they are harvested.”

“It means doing the absolute best at every stage of the production chain, from looking after the broodstock well, to giving the small fish in the hatchery the best environment in which to grow, to keeping predators away from Huon’s fortress pens, giving the fish the best possible diets and feeding them to appetite.”

With a number of onshore hatcheries and offshore pens, Huon has become Australia’s premier vertically-integrated salmon producer.

By far its largest source of revenue is salmon (Huon will grow to produce 23,000 tonnes of salmon this year), though it also farms some trout and produces secondary products like smoked salmon.

The company feeds its stock nutrient-rich, sustainable and often locally produced feed, and draws on industry-leading technology to control the feeding process for its fish stock, including software that can detect when the fish are full and turn off the supply of pellets.

The pens are also equipped with multiple cameras capable of tilting, panning and zooming, and probes for checking temperature and oxygen levels.

This allows staff to carefully monitor environmental conditions in each pen from offsite, and to move quickly to remove any dead fish from the pens and into an ensiling machine.

Other measures used to lessen stress in the fish stock is harvesting at night and crowding fish to prepare for harvesting in small numbers. Huon’s harvest system was the first of its kind in the world, Peter says.

“Our method uses the fish’s natural instincts to swim into a current where they go down a slide and are percussively stunned so that they undergo no stress prior to harvest. This is not only the most humane harvest system in the world, but it also greatly improves the flesh quality of the fish.”

This system won an award for humane farming methods from RSPCA UK. It means the process of harvesting the fish takes less than a second.

It’s just one of the innovative, high-tech features built into Huon Aquaculture’s facilities. “I believe the Huon method sets us apart from others in the industry and this is evident in the quality of Huon products.”

Peter says a recent visitor from a northern hemisphere counterpart commented that their own farm was “Third World in comparison to Huon’s practices”. He puts this difference down to the company’s commitment to keep pushing boundaries.

Our willingness to innovate and continually improve our farming practices is something that sets us apart.

Huon may have moved ahead of its international peers, but that doesn’t mean Peter thinks there is nothing it can learn from them. He gives the example of a remotely controlled feeding system that he and colleagues observed in Norway.

“That experience allowed us to get a better idea of the available technologies and to invent a system suited to our needs. But today, the tables are turned and people from Norway come here to look at our system.”

New developments

A turning point for the company came in 2013 when Peter recognised the business was in danger of stagnating or worse unless it changed direction.

The pens were continuously being raided by seals, a problem he says required “dramatic changes”.

From this grim situation came the opportunity to implement an industry-best system to keep Huon’s fish stocks safe, as well as ensure the safety of its staff.

“I had lots of ideas and we had already started designing our new fortress pen system,” he recalls. “I decided we needed to build the strongest pens in the world so we could farm offshore.”

Peter had determined that double netting was needed to prevent further seal attacks, but this change would bring with it a number of other alterations.

“Peter Bender has been a passionate and innovative leader within the industry. Peter’s deep understanding of aquaculture and strong strategic focus on continuous improvement has been a cornerstone for the success of Huon Aquaculture.” – Melissa Abbott, General Manager, Skretting Australia

In August 2013, Peter and colleagues visited a fish farming trade show in Norway. Peter had toured international facilities extensively and was especially keen to see what developments were taking place in Norway – the world’s foremost producer of Atlantic salmon.

By the time he was flying home, he was buzzing with ideas, but many of them needed to be heavily adapted to the very different Tasmanian conditions.

“I wrote down all my thoughts on basically changing the way we farm and emailed it to all my managers. The plan was to replace all our pens with fortress pens of our own design.”

The waters in Storm Bay, Tasmania, are significantly rougher than its Norwegian equivalents, so Huon Aquaculture needed to construct its own moulds for each component.

The scale of the project was immense and builders worked non-stop for three years to construct and commission the new pens. Aggressive local seals proved a persistent foe.

“With seals, you never know if you have beaten them until you have done the last pen. They will always go to the weakest one to attack first, so we breathed a great sigh of relief when we got the last pen done and our seal problem was fixed.”

The process may have been lengthy with a highly skilled workforce needed to run such modern salmon farms, but Peter says the results have been well worth it.

“I believe that Huon’s fortress pen system is the strongest and best in the world.” The system has now been fully rolled out and has held up in a range of weather conditions. The benefits to the fish are numerous; the double-netting offers protection from seals, which means they are less stressed.

The giant scale of the pens also allows for an average density of 99.5% water, meaning the fish have about seven times more space to move around in than free-range chickens.

The conditions also include higher levels of oxygen and a cleaner environment, resulting in better fish health. Huon hasn’t had to administer antibiotics to a single pen of seaborn fish since January 2016.

Further advances were made on the back of the company’s 2014 public listing, which raised the capital Huon needed to implement its Controlled Growth Strategy (CGS), budgeted at A$200 million. The CGS took two years to complete and was on time and on budget.

“The CGS is the key pillar of Huon’s overall growth and development,” Peter says. “It has brought benefits to each stage of the production process and supports long-term growth in production, increased operational efficiency and higher quality product.It has now been up and running for more than a year and the fish performance is exceptional.”

The CGS included the construction of Huon’s latest hatchery, Forest Home Hatchery, which is a leader in water recycling; it recycles more than 95% of the water it uses through the facility daily.

The strategy helped with the continuation of the upgrades that have allowed Huon to work at a much greater scale. Domestic demand for salmon is growing at around 10% a year, and it has become a staple of the Australian diet rather than the exotic item it was when Peter founded the company.

The future of fish farming in Tasmania

Huon has introduced best practice fish farming and invested in a whole gamut of innovative new technologies, but Peter says it also benefits enormously from its location.

“Tasmania is a fantastic part of the world to live and work in. I’ve spent my fair share of time travelling to other countries and I believe that I am very lucky to live and work in one of the friendliest and most beautiful places on earth. We also have the cleanest water and air in the world, which is a great advantage in a business such as ours. The Tasmanian clean green brand greatly assists us in many ways.”

Started as a small enterprise within the family business, Huon now has more than 550 staff and Peter takes great pride in the prominent role it has played in the community that he grew up in.

“AKVAGroup and Huon have a very exciting partnership where we share our combined aquaculture knowledge to develop technology and service solutions such as custom designed offshore barges and remotely operated net cleaners to meet the challenges of offshore salmon farming.” – Mike Thomson, General Manager, AKVAGroup Australasia

“It is very satisfying to provide people with meaningful jobs. Most of Huon’s employees are based in regional areas so, as a company, we are able to play a part in keeping rural Tasmania alive and well.”

More than 85% of Huon employees are locals and Peter adds that positions at the farm are highly skilled and specialised roles.

“A lot of people think that salmon farming is a ‘brawn not brain’ industry. In fact, it is actually very high-tech.”

The company is also concerned with ensuring that Tasmanian fish farming continues to be viable. “We are already thinking and planning for what the industry will look like in 2023 and how Huon will meet market demand while continuing to farm in an ethical and sustainable way.”

One avenue the company may explore further is land-based farming. In 2018, it will complete construction of a new nursery at Whale Point.

There are no current commercial examples of farms growing fish to harvest size entirely on land but Huon Aquaculture, ever the innovator, is interested in the possibility of growing salmon longer on land before they go to sea as a means of reducing biosecurity risks and improving environmental performance of sea sites by lengthening fallow periods.

A completely different revenue stream the company may pursue is tourism. Peter says some thought has been given to opening up the company’s facilities to visitors, though this is very much a long-term project.

“There is a lot of misinformation out there right now and we are working to correct this by focusing on educating the public about our farming practices. I do believe nothing can beat seeing the farm firsthand, so the potential is there in the future for guided tours.”

The heart of the business remains farming, however, and Huon Aquaculture has been a strong advocate for more vigorous regulation of the industry.

“The single largest opportunity for the salmon industry to secure long-term sustainability is the introduction of stricter biosecurity practices,” he says.

“We do a lot of innovative things in Tasmania, but there are also some important lessons to be learnt from overseas on the issue of biosecurity.”

Peter believes it is particularly important for regulators to take a proactive approach rather than waiting for a disaster to react to, a trap some international industries have fallen into.

Tasmania has been relatively free of exotic fish diseases that have been a bugbear for the industry in other countries, though some diseases have infiltrated farmed fish stocks through wild fish.

There are some measures in place to prevent the spread of diseases but Peter says more should be done by policymakers including keeping year classes of fish schools separate, and prohibiting the towing of fish stock past a competitor’s farm.

“If we don’t bring these practices into place, we will have more fish health issues in the future. This is something that industry and government need to work on together as, unfortunately, one farm on its own can’t solve this in the aquatic environment.”

Important Partnerships

Away from work, Peter restores and rides old English motorcycles, often meeting other members of his motorcycle club for a Sunday ride.

He has accumulated dozens of motorcycles, with pride of place going to a bike that set an Australian speed record back in 1953. His main passion, however, is farming and ensuring that fish are raised properly.

Part of keeping the company strong is recruiting people who are committed to the Huon method. “We bring people into the company who are open-minded and lateral thinkers,” he explains.

“That creates a healthy culture that is always on the lookout for a better way to farm, market, transport, sell and communicate.”

Just as new recruits are carefully chosen, new partners are scrutinised to ensure they are a close fit with Huon’s values. “When choosing potential partners to work with, I look for companies that are both innovative and flexible,” Peter says.

“For example, sometimes a prospective partner can offer technology that is almost right for what we need it to do, but they need to be willing to work with us to customise the equipment to our specifications and requirements and to Tasmania’s farming conditions.”

An example of a successful collaboration saw Huon Aquaculutre working with Norwegian company SolvTrans to construct a well-boat capable of bathing salmon in freshwater.

The fish need to be bathed in freshwater to prevent amoebic gill disease, which will cause lethargy and eventually death if it goes untreated.

Nobody had made a boat capable of being used for freshwater bathing. SolvTrans’ expertise proved hugely valuable, and the boat it constructed for Huon was the world’s first.

“We worked with SolvTrans to design a well-boat that could suck the fish out of the sea pens and remove the water so the fish could go into the wells,” Peter explains.

“The fish need to be removed from the freshwater tanks while retaining the water so that it could be used again for treating the next pen of salmon. All this is done without the fish going through any sort of pump. The level of technology on this vessel is mind-blowing.”

The 76-metre long vessel has the capacity to count and weigh every single fish that comes on board, produce oxygen, remove carbon dioxide and disinfect the water. It can operate 24 hours a day and holds over 3,000 tonnes of water.

Despite being a trailblazer in this area, Huon Aquaculture is already planning an upgrade, with a larger well-boat expected to be operational by 2019.

The new vessel will outstrip the current boat’s capacity significantly, holding more than 13,000 tonnes of water.

Despite such innovations and its commitment to humane farming methods, Peter says misconceptions about salmon farming persist.

“Some people think that our pens are crammed with fish when they are actually 99.5% water,” he laments. “People also think that our feed is full of chemicals, antibiotics and growth hormones, which couldn’t be further from the truth.”

To help address misinformation, Huon Aquaculture has introduced transparency measures through its online dashboard, which reports real-time information on environmental factors such as quantity of freshwater used, levels of dissolved oxygen, wildlife mortalities and seabed health.

It’s all part of the Huon method. “All of Huon’s farming practices, processes and logistics have the single goal of producing the best-quality salmon for consumers.”