No single route exists for business leaders to reach the top of their profession. Some start at the bottom of an organization and work their way up, while others earn a degree and gain expertise in the classroom before entering the boardroom.

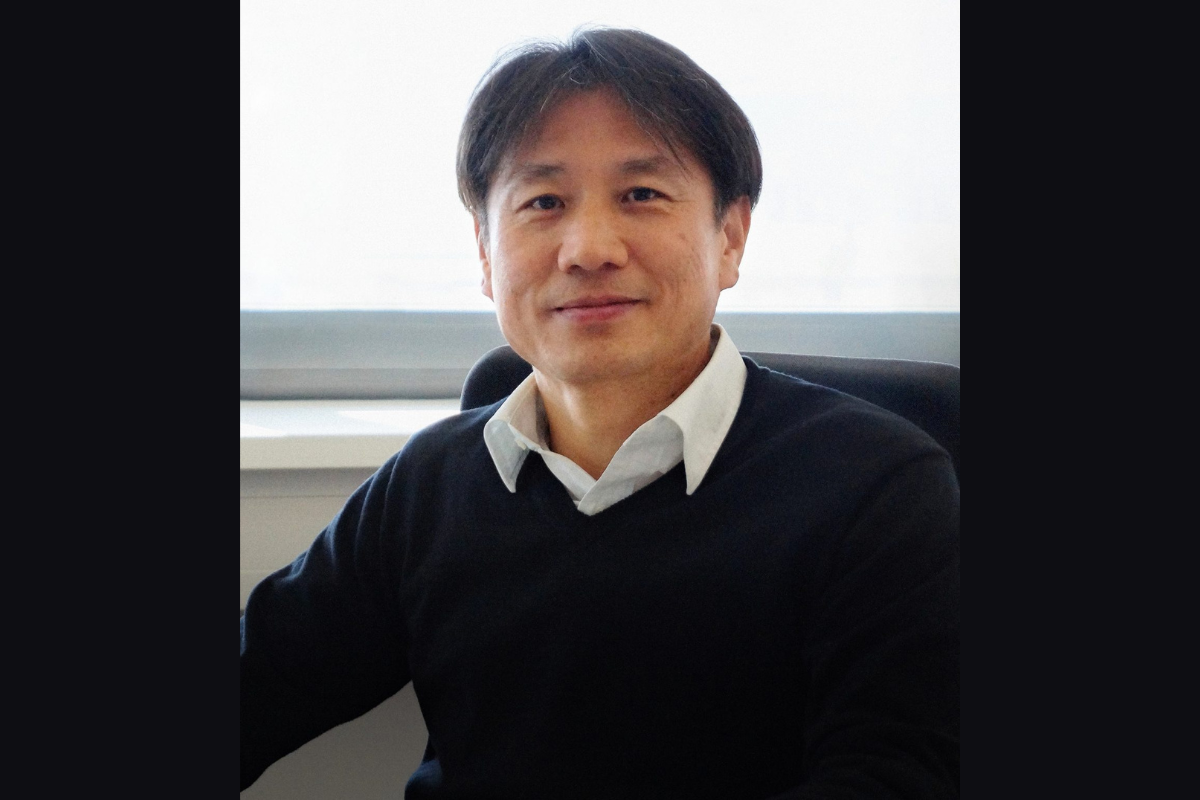

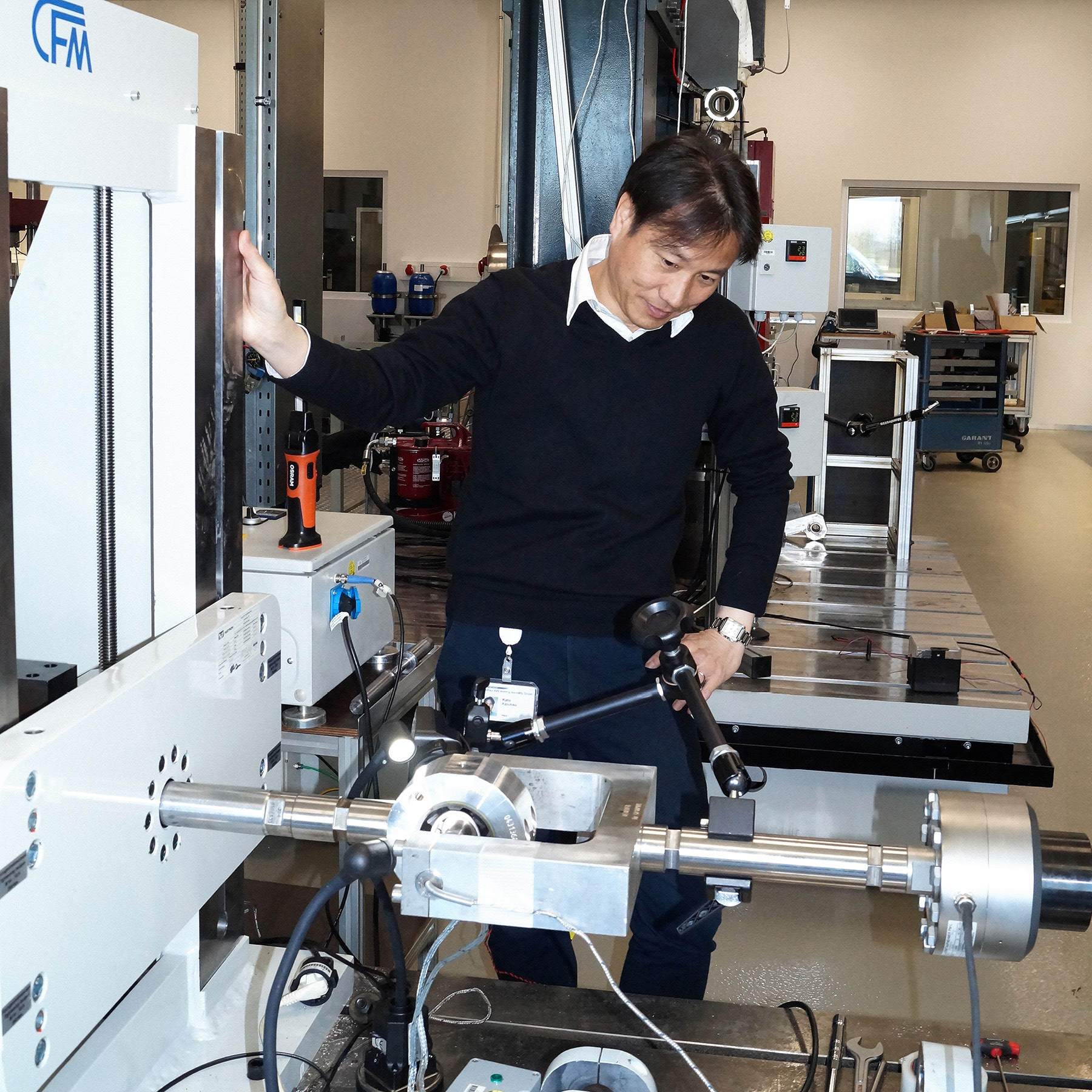

For Kazuhiko Kato, his background in engineering boded well for the corporate journey he was to experience when he became Managing Director of SumiRiko AVS Germany, part of Sumitomo Riko Group. The company specializes in the development and production of anti-vibration systems for the automotive industry.

In 1992, when Kato first joined Sumitomo Riko, or Tokai Rubber as it was then called, he worked for the design division.

“I started working in the Anti-Vibration Rubber team, and then I developed new products for AVS. Because of the customization of a typical Japanese Toyota, Nissan or Honda, I also worked with them,” he says.

He was soon promoted to manager of the division, and organized a team for Toyota and another for Honda. Kato says a major moment for both himself and Sumitomo Riko was in 2012 when the business set out to acquire the German company Anvis. “I led this acquisition, and later I moved to Poland as President of the sister company, SumiRiko Poland,” he explains.

We use big data, especially in our production process.

Market leader

While several competitors are directly competing with Sumitomo Riko for market share and customers, owing to its strength, Kato says he’s confident the business can continue to supply customers with leading products at competitive prices.

After purchasing Anvis, Sumitomo Riko has risen in the market to become first or second globally in its industry. Now that the company is supplying virtually all major customers in their sector with products, Kato is looking to maintain its current position and market share.

Part of the challenge right now is a shift toward electric vehicles, which is spurring Kato and his team to embark on a new strategy.

In practice, many products have to be changed, some to stop production entirely and others to be improved. Due to this shift, the business is seeking to analyze demand and work out how to be most effective in improving profits and sales.

The global supplier network established by Sumitomo Riko has also been an essential part of the formula for Kato’s success. Due to the many different divisions within the Sumitomo Riko Group, dozens of leading suppliers are used by the company, with parts of the enterprise in Poland, Japan and Germany often using the same supplier for some products to achieve better buying power.

Partnering with suppliers that fit in with the vision and mission that Kato has for the company is vital. Whether a potential supplier can offer a low price is not the only consideration, with the culture and brand heritage also playing a role in the company’s decisions, which come down to how these firms can grow with SumiRiko and benefit the end consumer.

Exact customer needs

“Our Japanese customers and European customers order similar numbers of products, but their requirements are a little bit different,” Kato explains. “That’s why we are considering how to make synergies as we develop, for Japan, the United States and also Germany, to develop similar products.”

While each customer expects slightly adapted products to best meet their needs, there are many opportunities for Sumitomo Riko to uncover synergies across the global production chain. “By doing this we will keep our presence, our sales and also increase our profit levels,” Kato says.

In Europe, Kato estimates that SumiRiko is probably sitting in third or fourth position, but he is ready to begin the fight to reach the top of the industry. He says the recent shift to electric batteries for vehicles is a positive sign for the company.

“Fortunately, we are successful with this new technology. So now we are ready to improve and to increase our market share. We would like to keep up with trends, with our R&D doing a very good job,” he adds.

Now we are ready to improve and ready to increase our market share.

The Sumitomo Riko Group has understood for some time the transformative power of embracing AI and machine-learning tools. According to Kato, utilizing AI will result in the production time of one operation being reduced by up to 30 percent – a significant improvement. A great deal of investment and focus has been placed on R&D, particularly when it comes to sustainability efforts.

Supplier Relations

SumiRiko has built up resilient supplier relationships and works hard to nurture this ecosystem. As with many other businesses, maintaining stable prices is an essential goal in discussions with suppliers, with close working arrangements supporting this aim.

“Toyota Motor Company works closely with us on management issues, safety issues, quality issues, even productivity,” Kato says. “They send people in to discuss or improve processes with us. This is probably, I think, a good relationship or cooperation with the supplier and the customer.”

“We use big data, especially in our production process,” he says. “Now our headquarters in Japan are also considering how to use these innovations. They have already started using big data tools to predict our future or our near-future market conditions. This is the most effective innovation for us.”