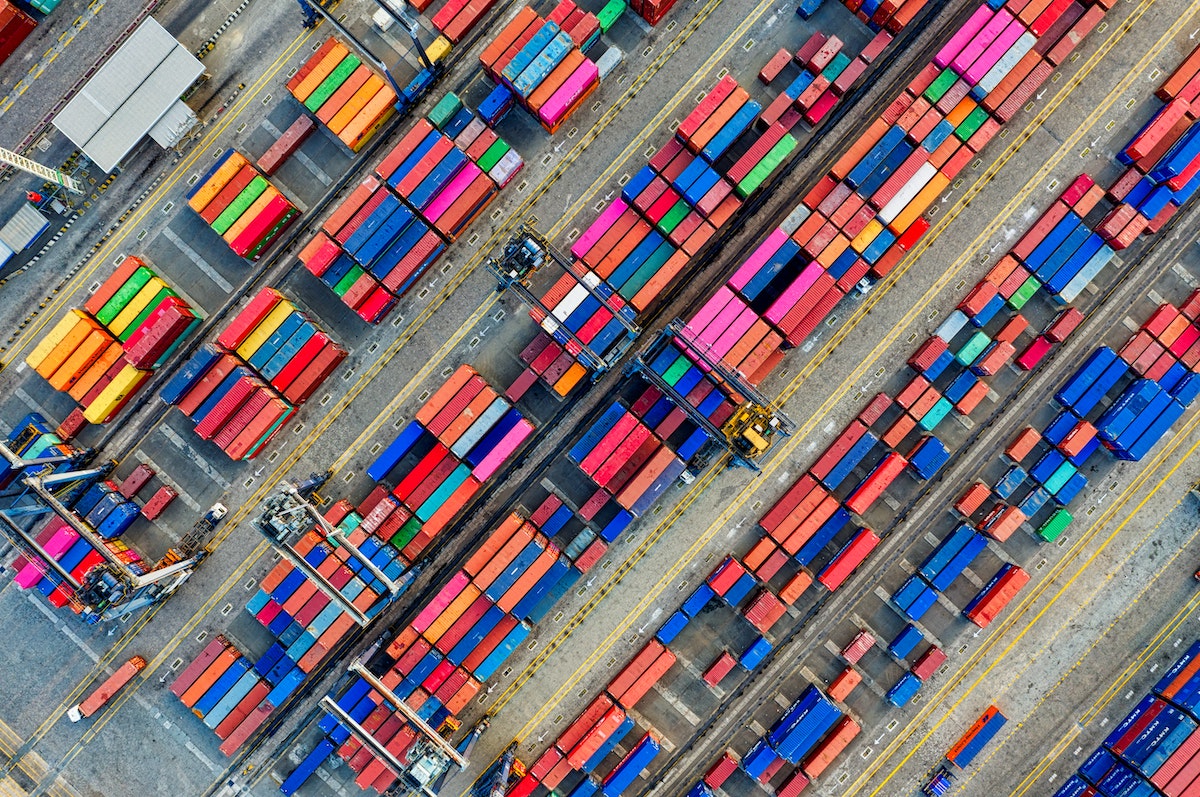

In the post-pandemic world of heightened risk, supply chain excellence is a critical difference-maker in business success or failure.

Great products only exist if they can be made and shipped reliably and cost-effectively to eager customers. And this can only happen if CEOs drive this from the very top.

The supply chain can no longer be a domain exclusive to logistics experts as the impact and consequence reaches all parts of the business. The most strategic leaders have realized genuine competitive edge in business today lies increasingly in the ability to master the new supply chain agenda.

Prevailing fears of disruption is leading to headline-grabbing geopolitical issues monopolizing the attention of CXOs and supply chain leaders.

EY’s ‘Supply Chain Reinvention’ white paper highlights the need to rethink the supply chain for the future. For business leaders, this means looking beyond the obvious with a deep analysis of all critical factors that can impact supply chain operations.

Key supply chain factors

Going forward, EY has identified five major factors that need to be proactively managed for global supply chain success. Geopolitical instability is predictably one of the five, but the other four factors merit equal attention.

Demographic shifts and urbanization

Location is more critical than ever. Global businesses are on a mission to build greater resilience by derisking and decreasing their reliance on just one or two supply chain hubs, chief among these China.

China will clearly remain a vital cog in global supply chain operations, but CXOs must now consider new complexities and the additional factors that shape supply chains today when implementing ‘China Plus One’ strategies, requiring a higher level of sophistication. Noting that manufacturing locations will increasingly be driven closer to the consumer, near-shoring to the largest consumer hubs is becoming the norm.

Businesses need ground-level insight on changing capabilities and market maturity to feed and inform decisions.

Vietnam, Thailand and Indonesia now offer low-cost but also quality alternatives to feed South-East Asian consumers. Malaysia continues to evolve its leading electronics capability, while India is emerging as a viable hub for electronics, automotive and other sectors, having improved its past infrastructure issues.

Businesses need ground-level insight on changing capabilities and market maturity to feed and inform decisions. Therefore, CEOs today should build an accurate heatmap of manufacturing and logistics capabilities by locations that align to critical business needs.

ESG requirements

CEOs that are serious about sustainability are incorporating ESG into supply chain metrics and embedding it as best practice. The reason is an unavoidable truth. EY research shows that more than 90 percent of an organization’s greenhouse gas emissions, and 50–70 percent of operating costs, are attributable to supply chains.

Supply chain leaders are now setting clear and measurable targets that extend across the whole supply chain ecosystem. Generating the required visibility will be a huge task given the complexity, capability and varied maturity of supplier networks in Asia. Global companies must build viable roadmaps for suppliers to evolve sourcing strategy, practices and materials to meet the new ESG requirements as well as changing regulatory needs.

Global companies must build viable roadmaps for suppliers to evolve sourcing strategy, practices and materials to meet the new ESG requirements as well as changing regulatory needs.

To lead and operate sustainably and ethically requires leaders who can effectively analyze their carbon footprint and ESG status across upstream and downstream networks. This journey begins with mapping out an organization’s entire end-to-end carbon footprint. The process will identify clear gaps, issues and opportunities for immediate improvement, which will form a more practical and achievable net-zero roadmap.

Technology race

Companies that adopt and integrate new technology quickly and effectively will handle supply chain reconfiguration faster and deliver better on business goals. Successful businesses will be those that can harness the emergence of AI, big data analytics, robotic, automation, IoT and more, to drive efficiency, agility, speed and visibility.

The race is relentless, but companies should avoid the obsession of fast and furious technology adoption. The leaders that separate from the pack will use technology exploration as a trigger to optimize operations and transform processes to be fit for success.

Technology only succeeds when applied to a process that is optimal and ready to benefit from it.

Great supply chains are fast, responsive, transparent and cheap. Technology only succeeds when applied to a process that is optimal and ready to benefit from it. Companies cannot hide or fix broken processes with technology.

Making it easier, the appetite for new technology will be matched by maturing solutions. Technologies like AI are becoming prevalent, with the majority of supply chain management application vendors planning to offer embedded AI and advanced analytics in the near to medium term. The growing availability of such advanced and mature capabilities can only help provide better visibility and insight for improved decision making.

Supply chain talent crunch

This is an acute challenge in Asia–Pacific as skills are less advanced and less available compared to the United States and Europe. Like technology, those that manage this effectively will be better equipped to make the right critical supply decisions that will make-or-break business. Skilled operatives need to distill data and situations from multiple domains such as market, political, ethical, people, process, technology and regulatory.

To achieve a best-in-class supply chain, upskilling today’s people in process, technology and a broader understanding of supply chain performance is essential. This applies to staff within the business but also to all people across suppliers and partner businesses too.

Just like technology, modern supply chain skills will be in short supply. Businesses will need to consider bolstering their approach to talent acquisition and retention by adopting hybrid work models and redesigning policies, cultures, technologies and facilities.

The Chief Supply Chain Officer

As supply chain discussions become a staple in the boardroom, Chief Supply Chain Officers have emerged as the ideal sparring partners for the CEO, and an increasingly common and loud voice. Likewise for the CEO and CXOs, a deep understanding of supply chain issues is now a critical skill set for any C-suite leader.

Some of the world’s leading CEOs today emerged from supply chain roles. Many have carried over their relentless focus on supply chain excellence into their leadership approach, proving to be invaluable in recent times.

A deep understanding of supply chain issues is now a critical skill set for any C-suite leader.

The ability to dissect multiple business indicators is the key to supply chain success. Without exception, all businesses should have a real-time dashboard to monitor and track all the above supply chain factors so that decisions can be made at the first sign of risk or imbalance.

Without this holistic view of a complete supply chain operation, picking the right levers to course correct will prove to be an impossible task. The art of supply chain management and ultimately navigating business today lies in being a master of keeping everything in play, all at the same time, and all the time.

Mads Lauritzen is EY-Parthenon Asia–Pacific Strategy and Transformation Leader. He specializes in enterprise-wide transformation and growth programs, and has a deep understanding of Asia, having lived in Korea, Japan, China, Taiwan and Thailand.